You’ve selected the powerful heart for your Renault Express Pickup conversion—a motor boasting 100+kW and 300+Nm of torque. But raw power alone isn’t enough. To truly harness this potential, create a smooth, efficient, and reliable electric vehicle, you need its digital brain: the Motor Controller. This critical component dictates how intelligently battery power is delivered to the motor, directly defining your driving experience, safety, and overall conversion success.

Choosing the right controller is not just about compatibility; it’s about unlocking performance. A well-matched controller ensures your motor delivers its peak torque smoothly from a standstill for impressive acceleration, manages thermal loads during sustained hill climbs with a load, and seamlessly recovers energy during braking to extend your range. For your Renault Express, a vehicle built for utility, the controller must be robust, smart, and perfectly adapted to your chosen motor and driving setup.

Key Selection Criteria: Matching Your High-Performance Motor

Your controller must form a perfect partnership with the motor. Based on the previously recommended motor specifications, here are the non-negotiable criteria for your controller:

-

Power & Current Rating (The Must-Match Spec): The controller’s continuous and peak current ratings must meet or exceed the demands of your 100kW+ motor. A controller underrated for the job will overheat, throttle power, or fail. Look for a unit rated for continuous current matching the motor’s nominal draw and peak current for short bursts of maximum acceleration.

-

Voltage Compatibility: It must operate flawlessly within your 300-400V battery pack’s voltage range. Furthermore, ensure it can handle the full charging voltage if using high-voltage DC fast charging.

-

Control Algorithm & Performance: The type of control algorithm (e.g., FOC – Field-Oriented Control) is crucial. FOC is now the industry standard for high-performance applications because it provides superior torque control, especially at low speeds (perfect for loaded starts), smoother operation across the entire speed range, and higher overall efficiency.

-

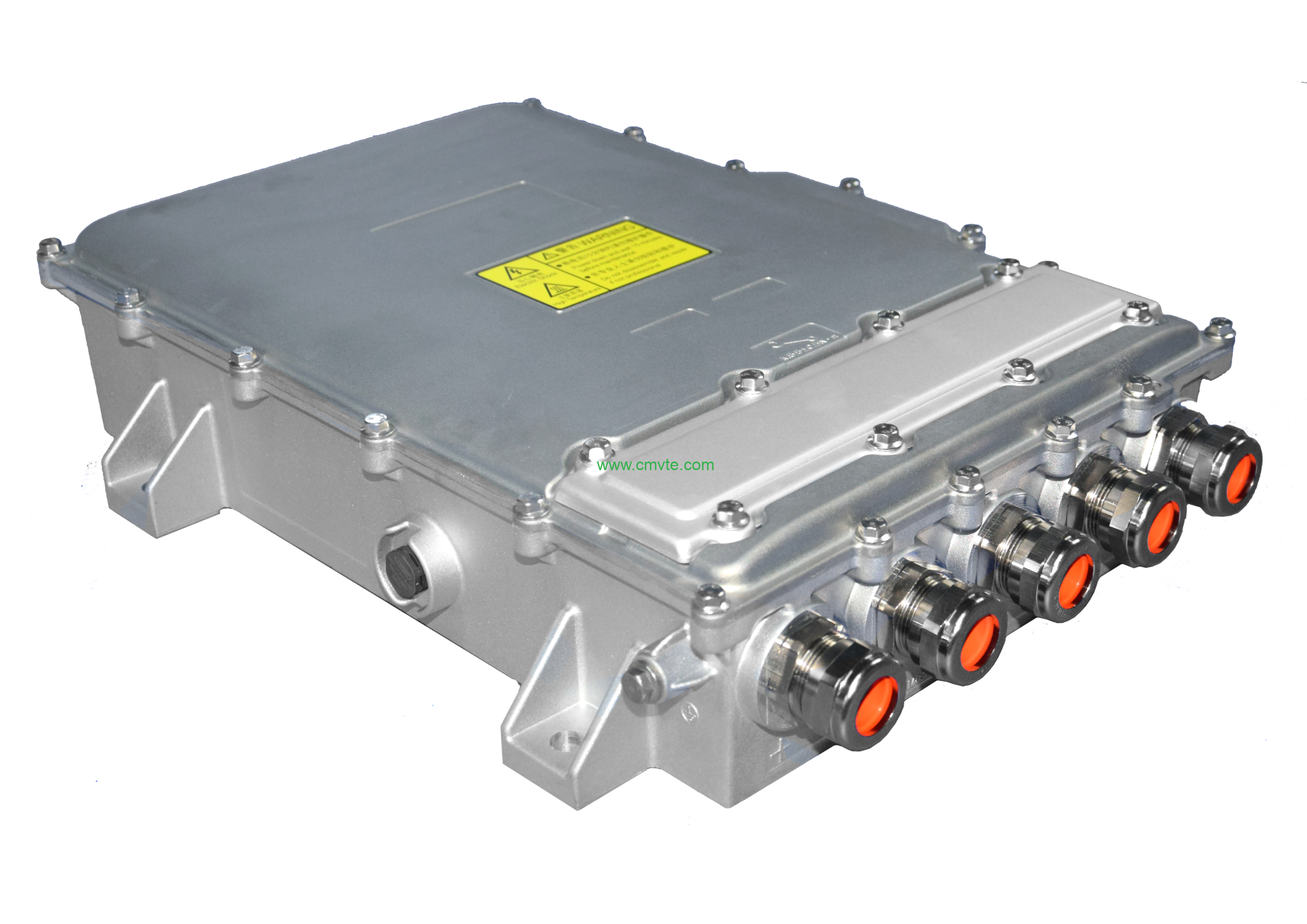

Cooling System: To handle the thermal demands of a commercial pickup, a liquid-cooled controller is highly recommended. It is far more effective at managing heat from high current flows than air-cooling, ensuring consistent performance and long-term reliability, which is essential for duty-cycle work.

-

Physical Form Factor & I/O: The controller must fit within your available space (often near the motor or battery box). Crucially, it must have the necessary Input/Output ports: throttle input, brake signal, CAN Bus communication for integrating with displays and battery management systems (BMS), and support for critical features like Regenerative Braking.

Integration Solutions: Tailoring to Your Drivetrain

The controller’s configuration is dictated by your chosen integration path, as defined in your motor selection:

-

Solution for Manual Transmission Integration: When retaining the original manual gearbox, the controller plays a sophisticated role. It must provide precise, low-speed torque control for smooth starts in first gear without jerking. The regen braking must be carefully calibrated to work in harmony with the traditional friction brakes and the engine braking effect of the gearbox. Programmable torque maps allow you to tailor power delivery for each gear if desired.

-

Solution for Direct-Drive (Automatic) Integration: In a direct-drive setup, the controller’s role is even more central. Without gears to multiply torque, the controller must ensure extremely smooth and linear torque delivery from zero RPM. The setup and fine-tuning of the regen braking system become the primary source of deceleration, requiring precise and intuitive calibration by an experienced technician.

Beyond Basics: Features for a Professional Conversion

For a conversion that feels OEM-quality, consider controllers that offer:

-

Programmability: The ability to fine-tune parameters like torque curves, regen strength, and throttle response is invaluable.

-

CAN Bus Integration: A modern controller should communicate seamlessly over CAN with your chosen instrumentation cluster and BMS for a clean, integrated system.

-

Safety & Diagnostics: Look for built-in protections (overcurrent, overtemperature, undervoltage) and diagnostic capabilities for easier troubleshooting.

Selecting a controller from a supplier with proven experience in light commercial vehicle conversions and strong technical support is as important as the hardware itself. The right partner can provide pre-configured settings, wiring schematics, and expert guidance.

Our CMVTE engineering team possesses deep expertise in matching high-performance motor-controller pairs for vehicles like the Renault Express Pickup. We can help you select the optimal unit and handle the critical integration and programming to ensure your converted pickup is not just powerful, but also refined, efficient, and dependable. Contact us to discuss the brain for your build.