The Nissan Skyline R32 is a classic performance sports car that has gained worldwide popularity. With the rise of electric vehicle conversion trends, more and more R32 owners are exploring how to transform this gasoline legend into a high-performance electric vehicle. This guide will comprehensively explain how to select the most suitable electric motor for R32 EV conversions, covering key aspects such as performance matching, installation integration, and cost control.

The R32, with its lightweight chassis, excellent front-to-rear weight distribution, and rear-wheel-drive layout, serves as an ideal platform for electric conversion. However, choosing the right motor is crucial, as it must preserve the car's original handling characteristics while fully leveraging the advantages of electric drive systems.

Table of Contents

ToggleUnderstanding Core Requirements for R32 EV Conversion Motors

When selecting a motor, it's essential to comprehensively consider performance goals, installation compatibility, and system matching. The original R32 came equipped with various engines ranging from the RB20E to the legendary RB26DETT, producing approximately 155 to 280 horsepower.

Key Performance Goals for R32 Electric Motors

- Power Output: 200-450 HP (approximately 150-335 kW), balancing street and track performance

- Torque: 300-650 Nm, ensuring rapid acceleration experience

- RPM Range: 0-10,000 RPM, providing a wide efficient operating range

- Weight: Preferably below 90 kg to maintain body balance

- Efficiency: Above 92%, optimizing range and energy efficiency

Layout Considerations for Motor Installation

The R32 engine bay was originally designed for the RB series inline-six engine, so motor placement requires careful planning. Most successful cases position the motor in the original engine location, using custom brackets connected to the original mounting points to maintain vehicle center of gravity and weight distribution ratio.

R32 EV Conversion Performance Targets

Mainstream Motor Options Recommendation

1. Tesla Rear Drive Unit (Latest Model)

| Specification | Parameters |

|---|---|

| Peak Power | 300-350 kW (approx. 400-470 HP) |

| Peak Torque | 600-700 Nm |

| Weight | Approx. 75-85 kg |

| RPM Range | 0-18,000 RPM |

| Cooling Method | Liquid Cooled |

| Features | Integrated inverter, high power density, supports fast charging, suitable for high-performance conversions. Requires custom brackets and half-shafts. |

2. Nissan Ariya / Latest Leaf Drive System

| Specification | Parameters |

|---|---|

| Peak Power | 160-220 kW (approx. 215-295 HP) |

| Peak Torque | 300-400 Nm |

| Weight | Approx. 60-70 kg |

| RPM Range | 0-12,000 RPM |

| Cooling Method | Liquid Cooled |

| Features | Good compatibility with Nissan systems, mature software support, suitable for balanced street conversions. |

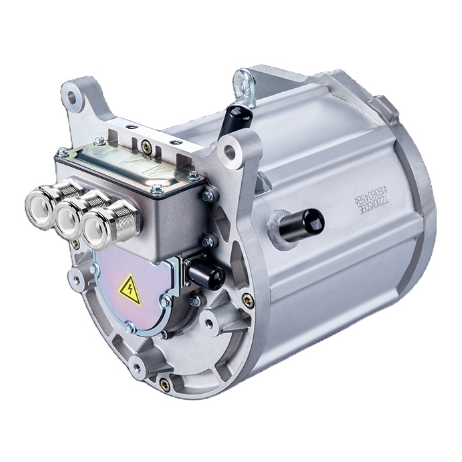

3. Specialized Conversion Motors (e.g., HPEVS, NetGain HyPer Series)

| Specification | Parameters |

|---|---|

| Peak Power | 100-150 kW (approx. 135-200 HP) |

| Peak Torque | 240-350 Nm |

| Weight | Approx. 70-80 kg |

| RPM Range | 0-8,500 RPM |

| Cooling Method | Air/Liquid Cooled options |

| Features | Designed specifically for conversions, abundant installation accessories, direct technical support, suitable for DIY enthusiasts. |

Installation Process and Key Considerations

Preparation and Planning

Before construction, remove the original engine, transmission, fuel, and exhaust systems. Depending on motor and battery layout, local reinforcement or openings in the chassis may be required. It's recommended to create 3D models or physical templates in advance to ensure spatial compatibility of all systems.

Motor Mounting and Bracket Fabrication

Brackets must withstand the motor's high torque output and ensure alignment with the drivetrain. Custom brackets made from steel plate or CNC-machined aluminum are commonly used, fixed through original mounting points, with consideration for vibration and noise isolation.

Drivetrain Integration Solutions

- Retain Original Transmission: Can utilize multiple gears, suitable for users pursuing traditional shifting feel and high-speed efficiency.

- Single-Speed Reducer Direct Drive: Simplified structure, reduced weight, more direct torque response, suitable for conversions seeking smoothness and low maintenance.

Professional Recommendation

When selecting a motor, consider not only peak power but also torque curve characteristics, cooling requirements, and compatibility with your chosen controller. Motors with wider efficiency ranges will provide better real-world performance and range.

Cost Analysis and Budget Planning

Main Component Cost Estimates (USD)

| Component | Economy Option | High-Performance Option |

|---|---|---|

| Electric Motor | $3,500 - $6,500 | $8,500 - $16,500 |

| Motor Controller | $2,000 - $4,200 | $5,500 - $11,000 |

| Battery Pack (60-80 kWh) | $8,500 - $14,000 | $16,500 - $27,500 |

| Charging System (OBC + DCDC) | $1,500 - $2,800 | $3,500 - $6,200 |

| Custom Brackets & Structural Parts | $2,100 - $4,200 | $5,500 - $11,000 |

| Professional Installation & Tuning | $2,800 - $5,500 | $8,500 - $16,500 |

Long-Term Value

Despite higher initial investment, an electrified R32 offers:

- Significantly reduced "fuel" and maintenance costs

- More linear power response and quieter driving experience

- Higher system reliability (few moving parts in electric motors)

- Future performance optimization through software updates

Conclusion

Selecting an electric motor for the Nissan Skyline R32 is a decision that combines engineering technology with performance passion. As electric drive technology matures and open-source solutions become more accessible, the barriers and costs for R32 EV conversions have become more reasonable. By clarifying performance goals, selecting appropriate motors and control systems, and meticulously executing installation and tuning, your electric R32 will not only延续 classic charm but also achieve new breakthroughs in power response, energy efficiency, and sustainability.

Ready to Convert Your R32 to Electric?

Get expert guidance and find the perfect motor solution for your Nissan Skyline R32 EV conversion project. Our specialists can help you select the right components and plan your conversion.