Table of Contents

ToggleUnderstanding the Key Differences Between BLDC and PMSM Motors: A Comprehensive Technical Analysis

Table of Contents

- Fundamental Concepts and Operating Principles

- Structural Differences and Design Characteristics

- Control Methodologies and Drive Systems

- Performance Characteristics and Efficiency

- Application Areas and Selection Guidelines

- Cost Considerations and Economic Factors

- Future Trends and Technological Developments

- Conclusion and Selection Summary

In the rapidly evolving field of electric motor technology, Brushless DC (BLDC) motors and Permanent Magnet Synchronous Motors (PMSM) represent two of the most advanced and widely used solutions across various industries. While both utilize permanent magnets and share some similarities in construction, they differ significantly in design, control methodologies, performance characteristics, and application suitability. This comprehensive analysis explores the key differences between these motor technologies to help engineers, designers, and technical decision-makers make informed choices for their specific applications.

Fundamental Concepts and Operating Principles

Brushless DC (BLDC) Motors

BLDC motors are electronically commutated DC motors that eliminate the need for physical brushes and commutators found in traditional DC motors. These advanced motors operate as an integrated system where the motor and controller function as a cohesive unit. The controller is essential for proper operation, as it precisely times the switching of currents in the stator windings based on rotor position feedback, typically from Hall effect sensors or encoder systems.

The fundamental operation of BLDC motors involves generating a rotating magnetic field in the stator that interacts with the permanent magnets on the rotor. This electromagnetic interaction produces torque, causing the rotor to turn. The control system continuously monitors rotor position and switches the current to appropriate windings to maintain smooth rotation. BLDC motors are characterized by their trapezoidal back electromotive force (EMF) waveform, which contributes to their distinct performance characteristics.

Key Insight: BLDC motors offer a excellent solution for applications requiring good performance with simpler control systems and lower cost implementation.

Permanent Magnet Synchronous Motors (PMSM)

PMSM motors operate on the principle of synchronous rotation between the stator's magnetic field and the rotor's permanent magnets. Unlike BLDC motors, PMSMs are designed as independent devices that can theoretically operate with various controllers or drives, though optimal performance requires carefully matched control systems.

These high-performance motors utilize a sinusoidal back electromotive force (EMF) waveform, which allows for smoother operation and more precise control compared to the trapezoidal back EMF of BLDC motors. The synchronous nature of PMSM motors means the rotor rotates exactly at the same speed as the stator's magnetic field, eliminating slip found in induction motors. This characteristic makes PMSMs particularly suitable for applications requiring precise speed control and high efficiency across variable operating conditions.

Structural Differences and Design Characteristics

While both BLDC and PMSM motors utilize permanent magnets on the rotor and polyphase AC windings on the stator, their internal designs differ significantly in ways that impact performance and application suitability. These differences extend beyond basic construction to influence efficiency, torque production, and control complexity.

| Feature | BLDC Motor | PMSM Motor |

|---|---|---|

| Back EMF Waveform | Trapezoidal | Sinusoidal |

| Stator Winding Distribution | Concentrated windings (full-pitch) | Distributed windings (short-pitch) |

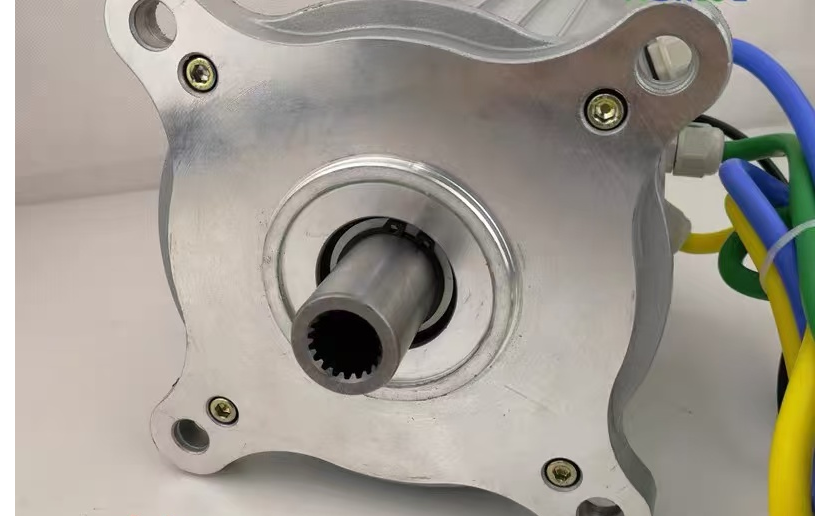

| Rotor Design | Surface-mounted permanent magnets | Often interior permanent magnets |

| Construction Complexity | Relatively simple | More complex |

| Torque Production | Discrete torque pulses | Continuous smooth torque |

| Cogging Torque | Generally higher | Minimized through design |

| Acoustic Noise | Higher due to torque ripple | Lower and smoother operation |

Control Methodologies and Drive Systems

BLDC Motor Control

BLDC motors typically employ a control strategy that aims to produce square wave current waveforms in each phase. This six-step commutation method energizes two phases at a time while leaving the third phase floating. The controller uses PWM (Pulse Width Modulation) techniques to regulate the output voltage of the inverter, which in turn controls motor speed and torque.

BLDC control systems are relatively straightforward, often utilizing Hall effect sensors for position feedback. The simplicity of the control algorithm makes implementation easier and reduces computational requirements, contributing to lower overall system cost. However, this simplicity comes at the expense of some performance characteristics, particularly torque ripple at lower speeds.

PMSM Motor Control

PMSM motors require more sophisticated control strategies to generate the sinusoidal current waveforms necessary for optimal operation. Advanced techniques such as Space Vector PWM (SVPWM) or Sinusoidal PWM (SPWM) are commonly employed. These motors often utilize field-oriented control (FOC) or vector control methods, which decouple torque and flux-producing current components for superior dynamic performance.

The control systems for PMSMs typically require high-resolution position feedback from encoders or resolvers, and more powerful processors to handle the complex mathematical transformations involved in vector control algorithms. This increased complexity translates to higher implementation costs but delivers superior performance in terms of efficiency, torque control, and operational smoothness.

Performance Characteristics and Efficiency

Efficiency Comparison

Both motor types offer high efficiency compared to traditional brushed motors, but they exhibit different efficiency characteristics across their operating ranges. Understanding these differences is crucial for selecting the right motor technology for specific applications.

BLDC Motors typically demonstrate excellent power efficiency, particularly at higher speeds. The trapezoidal control method reduces switching losses, and the absence of brushes eliminates associated losses. However, torque ripple can cause some efficiency reduction at low speeds. BLDC motors generally offer efficiency in the range of 85-90% under optimal conditions.

PMSM Motors generally offer higher overall efficiency, especially across variable speed applications. The sinusoidal excitation minimizes torque ripple and iron losses, leading to smoother operation and better efficiency at lower speeds. The vector control capabilities allow for optimal flux weakening at high speeds, extending the constant power range. PMSM motors can achieve efficiencies of 92-96% in well-designed systems.

Performance Note: While PMSM motors generally offer higher efficiency, the actual performance difference depends on the specific application requirements and operating conditions.

Application Areas and Selection Guidelines

The choice between BLDC and PMSM motors depends heavily on the specific requirements of the application, including performance needs, cost constraints, and control complexity. Each motor type has found its niche in various industries based on its inherent characteristics.

BLDC Motor Applications

BLDC motors excel in applications where cost-effectiveness, simplicity, and reliability are paramount. Typical applications include:

- Consumer appliances (washing machines, refrigerators, air conditioners)

- Computer peripherals (hard drives, cooling fans)

- Power tools and small machinery

- Electric bicycles and scooters

- Automotive auxiliary systems (pumps, fans, window lifts)

- Low-cost robotics and automation systems

- Medical devices where cost is a significant factor

BLDC motors are particularly suitable for applications requiring single-speed or stable-speed operation, typically in power ranges up to 300W, though higher-power applications exist.

PMSM Motor Applications

PMSM motors are preferred in applications demanding high precision, smooth operation, and excellent dynamic performance. Common applications include:

- Industrial servo systems and robotics

- CNC machinery and precision manufacturing equipment

- Electric and hybrid vehicle traction systems

- Renewable energy systems (wind turbine generators)

- High-performance HVAC systems

- Aerospace and defense applications

- High-end medical imaging and surgical equipment

- Precision motion control systems

PMSM technology is typically selected for higher-power applications (generally above 500W) where precise control of speed, position, or torque is required.

Cost Considerations and Economic Factors

The total cost of ownership for each motor type involves not just the initial purchase price, but also installation, control system requirements, maintenance, and operating costs over the system's lifetime. A comprehensive economic analysis is essential for making the optimal choice between these technologies.

BLDC motors generally have a lower initial cost due to simpler construction and less demanding control requirements. The sensors required for BLDC operation (typically Hall effect sensors) are relatively inexpensive, and the control algorithms can be implemented on lower-cost processors. This makes BLDC motors an attractive option for cost-sensitive applications where ultimate performance is not critical.

PMSM motors typically have a higher initial cost due to more complex construction, the need for high-resolution position sensors (encoders or resolvers), and more sophisticated control electronics requiring higher-performance processors. However, PMSM motors may offer lower lifetime costs in applications where energy efficiency and precision provide significant operational benefits that outweigh the higher initial investment. The higher efficiency of PMSMs can lead to substantial energy savings in continuous operation applications, while their superior control capabilities can improve product quality and manufacturing throughput.

Future Trends and Technological Developments

Both BLDC and PMSM technologies continue to evolve, with ongoing research focused on improving performance, reducing costs, and expanding application possibilities. The convergence of motor technology with digitalization and IoT capabilities is opening new frontiers in motor design and application.

Key areas of development include advanced magnetic materials with higher flux density and temperature resistance, integration of smart sensors and IoT capabilities for predictive maintenance, improved thermal management systems for higher power density, more sophisticated control algorithms leveraging artificial intelligence and machine learning, and hybrid designs that combine beneficial aspects of both motor types.

As motor technologies continue to advance, the distinction between these motor types may become less pronounced, with future designs potentially incorporating the best characteristics of both architectures. The trend toward electrification in transportation and industrial applications is driving innovation in both BLDC and PMSM technologies, with particular focus on improving power density, efficiency, and reliability.

Conclusion and Selection Summary

Understanding the fundamental differences between BLDC and PMSM motors enables engineers to make optimal selections for their specific applications, balancing performance requirements with economic considerations. When choosing between these motor technologies, consider the following guidelines:

Choose BLDC when cost is a primary concern, control simplicity is desired, and application requirements are less demanding in terms of precision and smoothness. BLDC motors offer an excellent balance of performance and cost for many consumer and industrial applications.

Choose PMSM when high performance, precision control, smooth operation, and efficiency across variable speeds are required, and higher initial cost is acceptable. PMSM technology delivers superior performance for demanding applications where precision and efficiency are critical.

As with any engineering decision, the optimal choice depends on a careful analysis of the specific application requirements, operating environment, performance expectations, and economic constraints.