In both daily life and industrial production, single-phase motors are ubiquitous. From household appliances like electric fans and exhaust fans to small machinery in factories, these motors play a crucial role. The winding resistance value of a single-phase motor is a critical parameter that directly impacts the motor's performance, lifespan, and operational stability. In this comprehensive guide, we'll explore this essential aspect of motor technology in depth.

Table of Contents

ToggleI. Significance of Winding Resistance

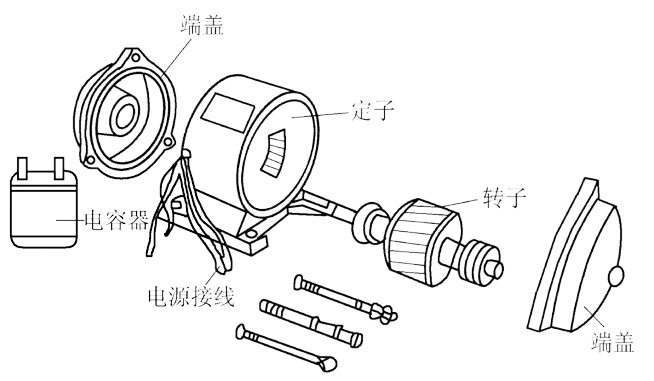

The winding of a single-phase motor functions like its "heart"—current flows through the winding, generating a magnetic field that drives the rotor to rotate. The winding resistance regulates the magnitude and flow of this current. When the resistance value is appropriate, the motor operates smoothly and efficiently. However, abnormal resistance values can lead to issues such as overheating, reduced power output, and even complete motor failure.

Understanding winding resistance is fundamental to motor design, operation, and maintenance. Proper resistance values ensure optimal performance, energy efficiency, and longevity. Incorrect resistance can cause excessive energy consumption, reduced torque, and premature motor failure. For technicians and engineers, the ability to measure and interpret winding resistance values is an essential skill for troubleshooting and preventive maintenance.

II. Reasonable Resistance Value Range

Generally speaking, the resistance value of single-phase motor windings typically falls between 0.5 and 5 ohms. However, this range is not absolute—different power ratings, types, and designs of single-phase motors will have varying winding resistance values.

Typical Resistance Values for Common Applications:

- Air Pump Motors: Typically around 4-5 ohms. The starting winding's number of turns, wire thickness, and reactance work synergistically to keep resistance relatively low, enabling quick starts and adaptation to high-load requirements.

- Electric Fan Motors: Approximately 1,000 ohms (1kΩ). This resistance range balances smooth fan operation with speed control capabilities, ensuring normal operation while facilitating effective speed regulation.

- Compressor Motors: Usually between 1-3 ohms, designed to handle high starting torque requirements while maintaining efficient running operation.

- Washing Machine Motors: Typically 2-4 ohms, balancing starting torque with operational efficiency for varying load conditions.

It's important to note that these values can vary significantly based on motor size, design, and manufacturer specifications. Always consult the motor's documentation for precise resistance values.

III. Factors Influencing Winding Resistance Values

Several factors contribute to the winding resistance in single-phase motors:

Wire Gauge and Number of Turns

In larger motors, the main winding typically uses thicker wire with lower resistance to carry higher working currents. Auxiliary windings often have smaller wire diameter with higher resistance. However, small motors present a more complex picture. Some low-power fan motors, with their small capacitance and low starting loads, may have windings with similar diameters, and in some cases, the auxiliary winding resistance may even be lower than the main winding resistance.

Winding Length

Starting windings, designed for capacitance phase shift, sometimes need to withstand double voltage and may be longer than main windings, resulting in higher resistance. However, in fan motors with multi-winding designs, if the main winding's total length exceeds that of the phase-shift winding, the resistance relationship may be reversed.

Manufacturing Processes and Materials

Modern motors often use fewer silicon steel sheets and fewer coil turns due to cost considerations and manufacturing simplifications, indirectly affecting winding resistance. Additionally, variations in the material and purity of enameled wire used in windings will be reflected in resistance measurements. Temperature also plays a critical role—resistance increases by approximately 0.4% per degree Celsius for copper windings.

IV. Applications of Winding Resistance Knowledge

Motor Fault Diagnosis

When a motor exhibits abnormalities such as weak operation, excessive heat, or failure to start, measuring winding resistance can help diagnose the issue. An infinite resistance reading typically indicates an open circuit or broken winding. Significantly lower than normal resistance suggests a short circuit within the winding. Winding resistance serves as a vital diagnostic indicator, enabling quick identification of problems and reducing maintenance time.

Motor Selection and Design

When developing new motor products or selecting motors for specific equipment, winding resistance is a key consideration. Different applications have varying requirements for starting characteristics and operational efficiency. Frequent start-stop applications in small household appliances need motors with specific winding resistance to ensure quick starts and energy savings. Industrial equipment requiring long-term stable operation needs winding resistance that maintains stable power output, reduces heat loss, and extends operational duration.

Motor Performance Optimization

Engineers can optimize motor performance based on winding resistance values. Adjusting winding turns, wire material, and other parameters can modify resistance to improve overall motor characteristics. In applications with strict energy efficiency requirements, appropriately increasing winding resistance (within reasonable limits) combined with other circuit optimizations can reduce no-load current, improve power factor, achieve energy-saving upgrades, and lower long-term operating costs.

V. Measurement Techniques and Maintenance Guidelines

Measurement Methods

Accurate measurement of winding resistance is essential for proper motor maintenance. The most common methods include:

- Digital Multimeter: Standard two-wire measurement suitable for basic checks

- Four-Wire Kelvin Measurement: Provides higher accuracy by eliminating lead resistance errors

- Specialized Motor Testers: Professional equipment that provides comprehensive winding analysis

Important Safety Precautions: Always ensure the motor is completely stopped and disconnected from power before taking measurements. Use professional instruments and ensure probe connections are correct and making good contact. If measurements show significant deviation from expected values, repeat the measurement to verify results.

High Resistance Issues

If resistance values are too high, possible causes include insufficient conductor cross-sectional area, too many joints, or poor connections. Solutions include increasing conductor size, reducing connection points, and ensuring all connections are clean and tight.

Low Resistance Issues

Abnormally low resistance may indicate excessive conductor cross-section, multiple parallel paths, or winding shorts. Appropriate adjustments should be made based on the specific cause identified through thorough testing.

Preventive Maintenance

Regularly test winding resistance as part of a preventive maintenance program. Document values over time to establish trends that can help predict potential failures before they occur. Clean windings periodically to prevent dirt and debris from affecting heat dissipation and potentially causing insulation breakdown.

Frequently Asked Questions

For critical applications, measure winding resistance during initial installation to establish a baseline, then periodically every 6-12 months depending on operating conditions. Motors in harsh environments or those subject to frequent starts/stops may require more frequent testing. Always measure resistance after any motor repair or rewinding.

Ideally, measure winding resistance when the motor is at ambient temperature (typically 20-25°C). If measured at other temperatures, use the formula Rcorrected = Rmeasured × [1 + α(Treference - Tmeasured)] where α is 0.00393 for copper. This converts the reading to the standard 20°C reference temperature for accurate comparison.

Yes, trending winding resistance values over time can help predict potential failures. Gradually increasing resistance may indicate developing problems with connections or winding degradation. Sudden changes in resistance often signify serious issues like short circuits or open windings that require immediate attention.

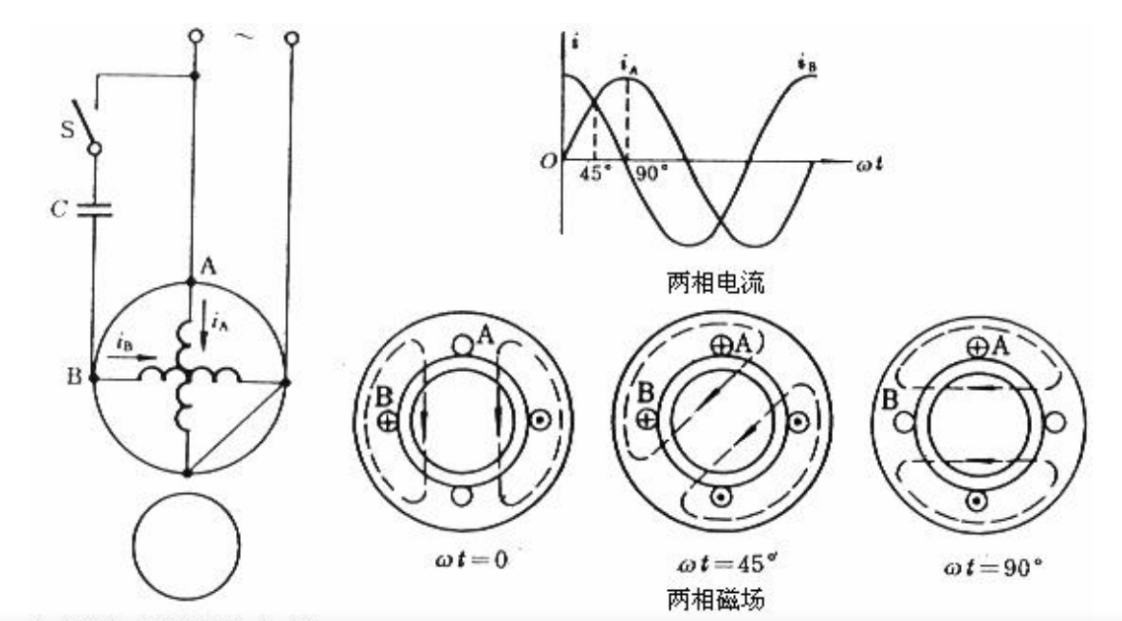

Main and auxiliary windings serve different purposes in single-phase motors. The main winding is designed for efficient running operation, typically with lower resistance and higher inductance. The auxiliary winding provides starting torque and often has higher resistance to create the phase shift needed for starting. The specific resistance ratio between windings depends on the motor's design and intended application.

For basic measurements, a quality digital multimeter with resistance measurement capability is sufficient. For more accurate measurements, especially on low-resistance windings, a micro-ohmmeter or a meter with four-wire Kelvin measurement capability is recommended. Always ensure your measurement equipment is properly calibrated and suitable for the resistance range you expect to measure.