Contents:

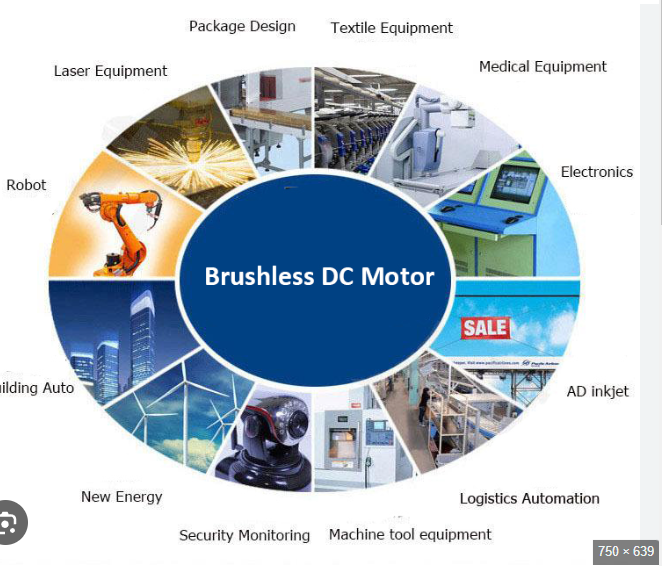

First, several different application scenarios of brushless DC motors

1.1: continuous load application;

1.2: Variable load application;

1.3: Locate applications.

Second, the advantages of DC brushless motor

Third, how to choose the right brushless motor according to the demand;

Four, the selection of brushless DC motor need to pay attention to several points of attention.

Fifth, the use of DC brushless motors on GMT products.

First, several different application scenarios of BLDC:

Brushless DC motor applications are very wide, such as automotive, tools, industrial control, automation and aerospace and so on. In general, brushless DC motors can be divided into the following three main uses:

1.1 Continuous load applications: mainly require a certain speed but the speed accuracy is not high in the field, such as fans, pumps, hair dryers and other applications, such applications are low cost and mostly open loop control.

1.2 Variable load applications: mainly applications where the speed needs to change within a certain range, and there is a higher demand for motor speed characteristics and dynamic response time characteristics. Such as household appliances, drying machines and compressors are a good example, the automotive industry in the oil pump control, electrical controller, engine control, etc., the system cost of such applications is relatively higher.

1.3 Positioning applications: Most industrial control and automatic control applications belong to this category, such applications often complete the transmission of energy, so the dynamic response and torque of the speed have special requirements, and the requirements of the controller are also high. The speed measurement may use photoelectric and some synchronization equipment. Process control, machine control, and transportation control are many of these applications.

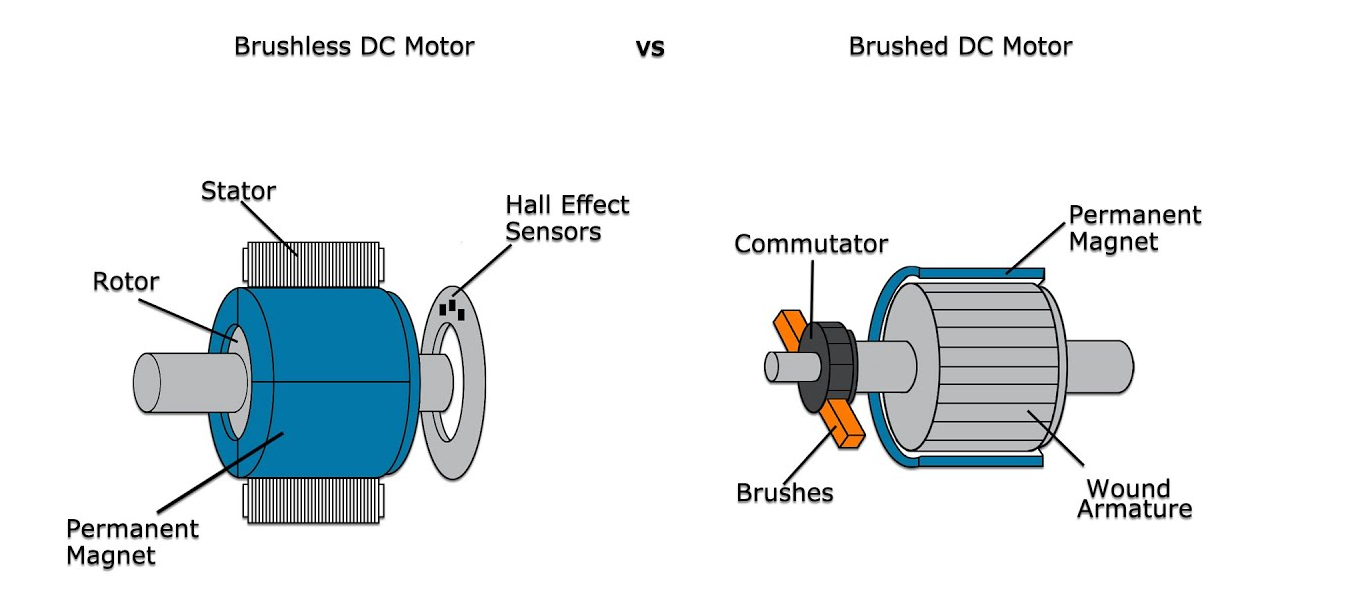

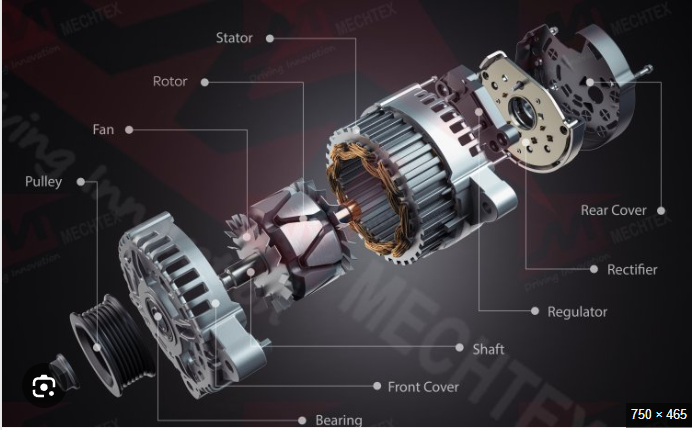

Brushless DC motor is a typical mechatronics product, which is composed of motor body and driver. Compared with the brushless motor, the brushless motor does not have the commutator in the traditional motor for commutation. As a result, brushless motors are structurally simpler and can achieve higher operating speeds and less mechanical wear. In addition, the brushless motor can also achieve more accurate speed control and running curve control by adjusting the parameters of the controller. Brushless motors are used in a wide range of applications, including home appliances, automobiles, robotics, aerospace, office automation equipment, and so on. Due to the high efficiency and superior performance of brushless motors, they have become one of the mainstream of modern motor technology.

Dc brushless motors have many advantages over traditional brushless motors:

High efficiency: Because there is no brush and commutator, the mechanical loss and brush loss of the brushless DC motor are smaller, and the efficiency is higher.

Long life: The brushless DC motor has no brush and commutator of the brush motor, and there is no problem that the brush and commutator need to be replaced because of wear, so the life is longer.

Precise control: The brushless DC motor can achieve more accurate speed control and running curve control by adjusting the parameters of the controller.

Wide range of applications: DC brushless motor can be used in household appliances, automobiles, robots, aerospace, office automation equipment and other fields.

Low speed high torque: DC brushless motor has the characteristics of low speed output high torque, suitable for occasions requiring large starting torque.

High speed performance: brushless DC motor has higher stability and less noise when running at high speed.

Good regenerative braking effect: the rotor of the DC brushless motor is a permanent magnet material, which can enter the generator state when braking, and the regenerative braking effect is better.

Small size, light weight: brushless DC motor compared with brush motor, smaller size, lighter weight, easy to carry and install.

Good protection: DC brushless motor uses a fully enclosed structure, better protection, can prevent dust and moisture into the motor inside.

Compared with traditional brushless motors, brushless DC motors have the advantages of higher efficiency, longer life, more accurate control, wider application range, better low speed and large torque performance, better high-speed performance and regenerative braking effect, and better protection performance.

Dc brushless motor is a common motor, it is used in all kinds of mechanical equipment, with higher accuracy and less noise, and can meet a variety of special motion control requirements. Because of its advantages, DC brushless motor is more and more used in various industries, but because of its complex selection, many people will encounter some difficulties in selection. We can discuss the selection of DC brushless motors from six angles below to find the most suitable model.

First, the model book

For the selection of DC brushless motors, we first need to understand the various types of models. At present, the common DC brushless motor models can be roughly divided into: DC brushless motor model, electromagnetic speed control brushless DC motor model, DC speed control brushless DC motor model, air cooled brushless DC motor model, water cooled brushless DC motor model, liquid cooled brushless DC motor model.

Second, installation structure

When selecting a DC brushless motor, it is necessary to choose according to the installation structure. The installation structure of DC brushless motor includes suspension type, two-axis type, axial stator structure and pedal type. Among them, the suspension installation structure is suitable for heavier equipment, the two-axis installation structure is suitable for lighter equipment, the axial stator structure is suitable for high-precision equipment, and the pedal installation structure is suitable for smaller equipment.

Third, power

When selecting a DC brushless motor, you also need to consider the size of the power, the greater the power, the faster the motor speed, but the power consumption will be greater, therefore, you need to determine the power size according to the actual demand. Under normal circumstances, the motor power for small mechanical equipment is generally below 200w, the motor power for medium-sized mechanical equipment is generally 200-500w, and the motor power for large mechanical equipment is generally above 500w.

Forth. Current

The current of the DC brushless motor is also an important factor to consider, the greater the current, the greater the power of the motor, but it will also consume more power, therefore, when selecting the DC brushless motor, the size of the current needs to be considered to determine the most appropriate current value.

Fifth. Frequency

For DC brushless motor, frequency is also an important selection factor, the higher the frequency of the motor, the faster the speed, but the power consumption will be greater, therefore, in the selection, according to the actual needs to determine the most appropriate frequency

Sixth. Noise

The noise of DC brushless motor is also an important factor to consider, the noise of DC brushless motor is generally only about 50 decibels, much lower than the noise of other motors, therefore, in the selection, we should also consider the size of the noise to determine the most suitable motor.

The selection of DC brushless motor should consider the model, installation structure, power, current, frequency and noise and other factors, only by taking these factors into account can we determine the most suitable model to meet the needs of customers.

In the selection of DC brushless motor we also need to pay attention to the following points:

First of all, when selecting DC brushless motor products, the correct voltage should be selected, and the rated voltage should be selected according to the needs of customers to select the driver voltage parameters, paying attention to the voltage used in the no-load and full load process should not exceed the range specified by the driver.

Secondly, we choose the peak current of the driver, the method of selecting the peak current is the rated input current Ir(A) of the known motor, then the peak current Ip(A)≥2Ir, otherwise there is no certain engineering margin for the output current during the use of the driver. If the rated output power (or maximum output power)Pr(W) and drive voltage Vr(V) of the motor are known, the peak current Ip(A)≥4Pr/Vr.

In addition, in the selection of DC brushless motor, to consider the change in temperature, the wider the temperature change, the price will be more expensive, and will affect the life of the motor.

In addition, also consider the power insulation requirements, in order to ensure the normal operation of the driver, the DC brushless motor hall ground wire and motor winding insulation resistance need to meet the requirements, can withstand a certain breakdown voltage.

The selection of brushless DC motor also needs to pay attention to details, such as the interface type of brushless motor, moment of inertia and so on. At the same time, you need to ensure that the selected motor is perfectly compatible with your control system for more efficient control.

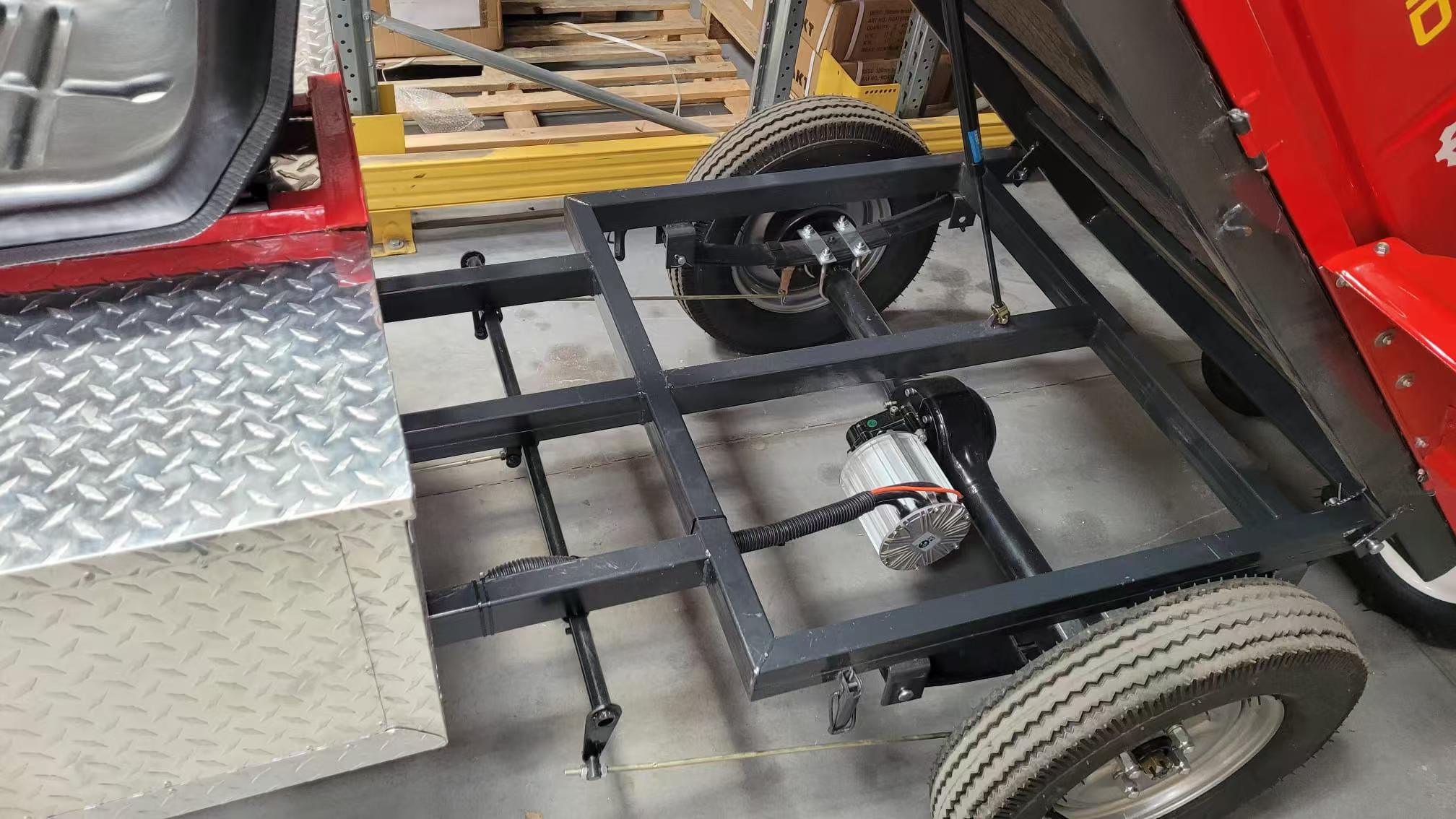

According to the various characteristics and functional advantages of BLDC, GMT applies BLCD to a large number of motorcycle and tricycle modifications. Fully highlight the advantages of BLDC. And won a large number of customer praise.