An Efficient Power Solution Based on a 144V PMSM Motor Controller Kit

1. Background and Problem Statement

Current Situation:

The customer owns a classic VW Beetle that had previously undergone an initial electric conversion, equipped with an old DC series wound motor.

Pain Points & Requirements:

The customer wanted to modernize the powertrain by replacing the outdated DC motor with a higher-performance DC permanent magnet or AC motor.

Technical Constraints:

-

Voltage Platform: The existing battery pack is configured for 144V, and the new motor must be compatible with this voltage level.

-

Mechanical Connection: The current motor is connected to the original transmission via an adapter. The new solution must retain or optimize this mechanical interface.

-

Power Expectation: The desired rated power range is 20kW – 50kW to ensure adequate vehicle performance.

2. In-Depth Requirement Analysis

For “ICE-to-EV” or “EV upgrade” projects on classic vehicles like the VW Beetle, the core challenge lies in balancing weight, space, and performance:

-

Power Matching: The Beetle’s lightweight body means excessive power could damage the original drive shafts, while insufficient power would lead to poor hill-climbing ability. The 20–50kW range is ideal, covering needs from city cruising to highway driving.

-

System Efficiency: The 144V platform operates at a medium-high voltage. Compared to low-voltage systems (48V/72V), it draws lower current at the same power level, reducing line losses and helping extend driving range.

-

Space Limitations: The rear engine compartment of the Beetle is limited, requiring a compact motor design.

3. Technical Route Selection: Why Recommend PMSM?

When responding to the customer’s inquiry about “DC permanent magnet vs. AC induction,” CMVTE’s technical team conducted a detailed comparison and ultimately recommended the PMSM (Permanent Magnet Synchronous Motor) solution.

3.1 Comparison with DC Series Wound Motor

-

Efficiency & Thermal Management: Traditional DC motors are less efficient, generate significant heat, and lack effective regenerative braking capability. PMSM typically achieves over 95% efficiency and offers excellent thermal performance.

-

Maintenance Cost: DC motors usually contain brushes that require regular replacement. PMSM is brushless, enabling truly maintenance-free operation.

-

Driving Experience: Combined with a controller, PMSM enables precise torque control, delivering a much smoother drive compared to traditional DC motors.

3.2 Comparison with AC Induction Motor

-

Torque Density: For the same volume and weight, PMSM offers significantly higher torque density than induction motors—a critical advantage in the Beetle’s tight engine bay.

-

Low-Speed Performance: PMSM is more efficient at low to medium speeds (typical city driving conditions) and provides more immediate torque response at startup, making it well-suited for direct connection to the original manual transmission.

-

System Complexity: Induction motor systems tend to be heavier and require more complex control algorithms. The PMSM solution is lighter and better meets the strict weight distribution requirements of classic car conversions.

4. CMVTE’s Solution

Based on the analysis above, we provided the customer with a customized, one-stop solution:

-

Core Product: 144V 25kW PMSM Motor Controller Kit

-

Rated Power: 25kW (peak power can reach 50–60kW), perfectly matching the customer’s requirements.

-

Voltage Compatibility: 144V system voltage, directly compatible with the customer’s existing battery pack.

-

Mechanical Features: Standard flange interface allows easy connection to the VW Beetle’s original transmission via an adapter plate.

-

Custom Conversion Plan:

-

Provided actionable conversion guidelines tailored to the customer’s specific model year and chassis structure.

-

Included motor positioning calibration, controller wiring recommendations, and cooling system planning.

-

-

Global Logistics Support:

The customer is located in Australia, requiring international shipping. CMVTE provided a complete logistics package, including customs clearance assistance, to ensure the heavy motor kit was delivered safely and on time.

5. Implementation Process & Key Considerations

During the project implementation phase, CMVTE emphasized the following details:

-

Mechanical Adaptation: Precision machining of the adapter plate was crucial to ensure concentricity between the motor shaft and transmission input shaft within tolerance, preventing vibration and noise.

-

Electrical Safety: With a system voltage of 144V (classified as high voltage), we guided the customer to strictly follow high-voltage electrical safety protocols during installation, including wiring harness shielding, emergency stop switch setup, and insulation testing.

-

Calibration & Tuning: Using supporting software, the controller was finely calibrated to adjust acceleration curves and regenerative braking strength, balancing the Beetle’s classic driving feel with the responsive performance of an electric vehicle.

6. Final Outcome & Customer Feedback

-

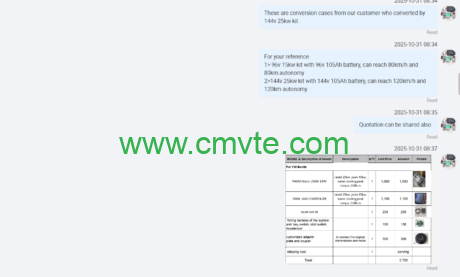

Solution Validation: After reviewing the detailed proposal and CMVTE’s previous VW Beetle conversion cases (images/video data), the customer highly acknowledged our professionalism.

-

Successful Conversion: The customer adopted the PMSM solution and completed the kit purchase.

-

Project Value: This case successfully demonstrates that the 144V PMSM kit is a mature solution offering the best balance of performance, cost, and reliability for VW Beetle electric conversions on the market today.

Conclusion:

For VW Beetle owners worldwide, upgrading from an outdated DC motor to an efficient PMSM system is not only a power upgrade but also a continuation of classic automotive heritage. Through professional technical selection, customized solution design, and borderless logistics services, CMVTE ensures that every Beetle can be reborn in the electric era.