Imagine: when you're driving a new energy vehicle at high speed, or your washing machine is operating efficiently, one of the heroes behind the scenes might be the PMSM motor. What kind of "speed and passion" is hidden inside this compact power source? How does it precisely convert electrical energy into mechanical energy to drive our modern life and industrial operations? This article will provide an in-depth analysis of the working principle, core technology, and wide applications of PMSM motors.

Table of Contents

ToggleBasic Structure of PMSM Motor: A Precise "Magnetic Factory"

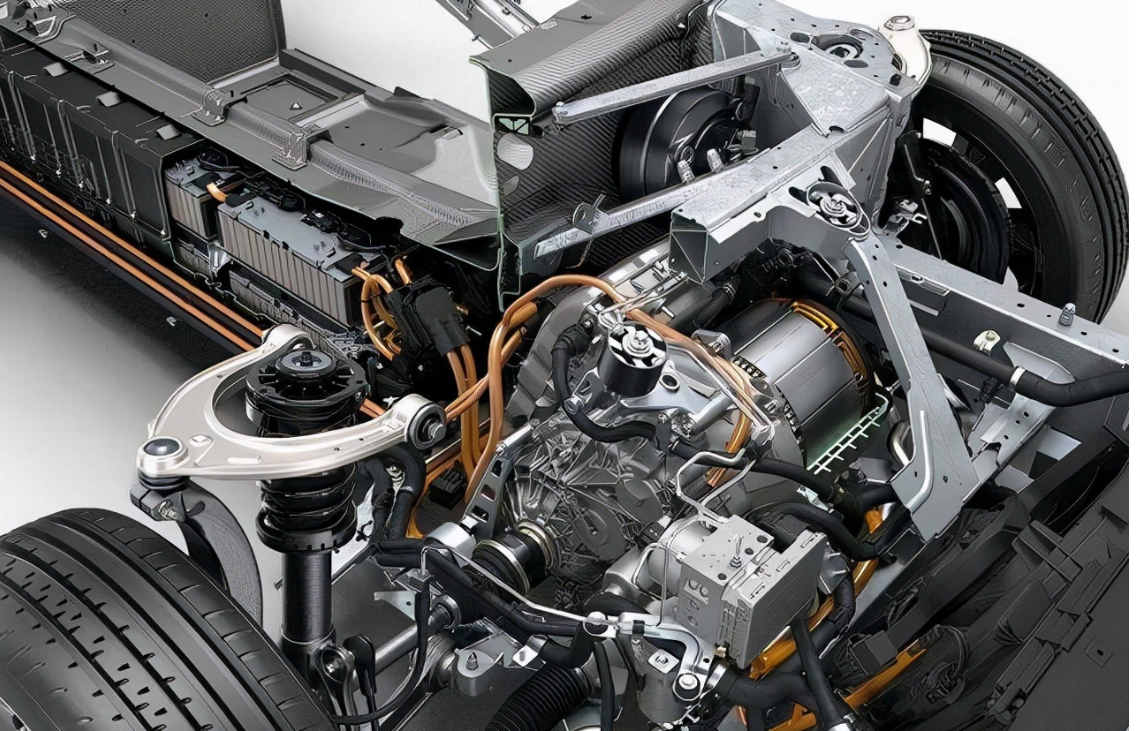

First, let's understand the basic structure of the PMSM motor. Simply put, it's like a miniature "magnetic factory." Its core components are the stator and rotor, which work together to achieve efficient conversion of electrical energy to mechanical energy.

Stator: The Core That Generates the Driving Magnetic Field

The stator is the stationary part of the motor, containing windings. When alternating current passes through the windings, it generates a rotating magnetic field.

- Precision Windings: Modern PMSM motors use high-quality copper windings and advanced insulation materials to maximize efficiency and thermal performance.

- Optimized Design: The precise arrangement of windings is designed to generate a smooth, continuous magnetic field that interacts with the rotor's permanent magnets while minimizing energy loss and achieving higher power density.

Rotor: Permanent Magnets Provide Constant Magnetic Field

The rotor contains permanent magnets that create a constant magnetic field.

- Powerful Magnets: These magnets are typically made of rare earth materials like neodymium, providing strong magnetic fields in compact sizes.

- Magnet Arrangement: The arrangement of magnets is crucial to motor performance. Common configurations include surface-mounted magnets, interior permanent magnets, and spoke-type designs, each with advantages in torque generation, speed range, and structural integrity.

Control System: The Brain of the Motor

PMSM motors require complex electronic controllers to operate properly.

- Precise Control: These controllers use sensors to determine rotor position and apply appropriate current to the stator windings at precise moments.

- Advanced Algorithms: Advanced algorithms, particularly Field-Oriented Control, enable PMSM motors to maintain high efficiency across various speeds and loads, making them ideal for applications requiring precise speed and torque control.

Vector Control Technology: The "Secret Weapon" for Precise Control

So how does the PMSM motor achieve precise control? This is where its "secret weapon" comes in - Vector Control Technology.

Vector control is like a highly skilled "choreographer" that decomposes the motor's current and magnetic field into two independent components: direct-axis component and quadrature-axis component. In this way, the originally complex motor control problem is simplified into two smaller problems that can be handled independently, just like breaking down a complex dance into basic steps that can be tackled one by one.

Through vector control, the motor's current and magnetic field can be precisely adjusted, achieving accurate control of speed and position. This is like a choreographer in a ballroom who can flexibly adjust the dancers' movements and steps according to the music rhythm and dance requirements, making the entire performance smoother and more elegant.

Whether it's new energy vehicles that need high-speed operation or industrial robots that require precise positioning, PMSM motors can easily handle them with vector control technology.

Wide Application Scenarios of PMSM Motors

Next, let's explore the application fields of PMSM motors through some practical cases.

🚗 New Energy Vehicles

PMSM motors play a crucial role in the field of new energy vehicles.

- Core Driving Force: With their high energy conversion efficiency and powerful power output, they enable vehicles to accelerate quickly in a short time.

- Performance Paradigm: Taking the Tesla Model S Plaid as an example, its equipped PMSM motor is one of the keys to achieving excellent performance, with the vehicle having a range of over 600 kilometers.

- Technical Parameters: Advanced new energy vehicle PMSM motors can reach maximum speeds of over 20,000 RPM, peak torque exceeding 1,400 Nm, and power density reaching an astonishing 3.6 kW/kg or more, providing an unparalleled driving experience.

🏭 Industrial Automation

PMSM motors are also widely used in the field of industrial automation.

- Robot Core: On production lines, industrial robots need to accurately perform various complex actions such as grabbing,搬运, and welding. PMSM motors, with their high precision and high response speed, can well meet the needs of industrial robots.

- Precise Operations: In automobile manufacturing plants, industrial robots equipped with PMSM motors can accurately complete the assembly of automobile parts, improving production efficiency and product quality.

- Performance Indicators: PMSM motors for industrial robots can achieve positioning accuracy of ±0.01 mm, response time of only 2 milliseconds, and maintain stable performance at high speeds.

🏠 Household Appliances

PMSM motors are also ubiquitous in the home appliance field.

- Energy Saving and Quiet Operation: Washing machines, air conditioners, refrigerators and other home appliances all extensively use PMSM motors. Taking washing machines as an example, PMSM motors can provide stable speed and strong torque, making washing machines more stable and quieter during the washing process.

- Energy Efficiency Improvement: The energy-saving effect of PMSM motors also improves the energy efficiency level of washing machines, saving users electricity costs.

- Energy Efficiency Standards: Washing machines using PMSM motors can reach National Level 1 Energy Efficiency Standards, with energy saving effects improved by over 30% compared to traditional motors.

CMVTE's PMSM Motor Solutions: Empowering Electric Conversions

As a seasoned supplier in the field of new energy vehicle conversion accessories, CMVTE's 5kW--350kW Permanent Magnet Synchronous Motor Systems provide efficient and reliable solutions for converting traditional fuel vehicles to electric vehicles.

Solution Advantages

- Excellent Performance: The motor system has characteristics of high efficiency, high torque output, stability and reliability, which can significantly improve energy utilization and driving performance.

- Intelligent Control: Through intelligent control systems, retain the driving habits and operation methods of fuel vehicles, balancing nostalgia and practicality.

- Wide Applicability: Whether it's the electrification of classic models, power upgrades for high-performance electric vehicles, or economical and environmentally friendly conversions for urban commuter vehicles and commercial vehicles, CMVTE's motor systems can meet diverse needs.

Application Scenarios

- Classic car electrification conversion

- High-performance electric vehicle power upgrade

- Commercial vehicle electrification solutions

- Personalized custom electric conversion

Key Characteristics and Advantages of PMSM Motors

PMSM motors have many amazing characteristics that make them stand out in various application fields:

High Efficiency and Energy Saving

- Ultra-high Efficiency: Like an "energy-saving expert," it can maximize the conversion of electrical energy into mechanical energy, reducing energy waste. Under rated load, efficiency can reach over 90%.

- High Power Factor: Power factor can usually reach over 0.95, reducing reactive power loss.

Simple Structure and High Reliability

- Simple Design: Simple structure, no complex excitation device, like a "minimalist," saving a lot of unnecessary trouble.

- Low Maintenance Cost: Brushless design eliminates brush wear and related maintenance needs.

Excellent Performance

- High Power Density: Compared with other motor types, PMSM motors can provide greater power per unit volume.

- Excellent Speed Regulation Performance: Achieve precise speed regulation within a wide working range.

- Smooth Operation: Smooth torque output brings lower operating noise.

- Long Service Life: Sturdy structure and wear-free components ensure longer service life.

Future Development Trends of PMSM Technology

With continuous technological progress, PMSM motors are constantly developing to meet increasingly demanding application needs. Research mainly focuses on the following key areas:

- Advanced Magnetic Materials: Develop magnets with higher energy density and reduced rare earth content.

- Thermal Management Technology: Improve cooling systems to cope with higher power density.

- Integrated Design: Integration of motors and controllers to achieve compact, efficient packaging.

- Sensorless Control: Advanced algorithms eliminate the need for position sensors.

- Wide Bandgap Semiconductors: Use SiC and GaN devices to create more efficient controllers.

These advances will further enhance the performance, efficiency and applicability of PMSM motors in various industries, consolidating their position as the preferred choice for high-performance electric drive systems.

Conclusion: The Power Core of the Intelligent Era

Finally, let's summarize the working principle of the PMSM motor with an interesting analogy. Imagine you're playing a racing game and need to precisely control the speed and direction of the car. At this point, the PMSM motor is like a super intelligent "racing engine," and vector control technology is your "control handle." By flexibly adjusting the handle, you can make the car race on the track, whether it's straight-line acceleration or corner drifting, it can handle it with ease. The high efficiency, simplicity and power of the PMSM motor ensure that your car is always in the best condition, allowing you to fully enjoy the "speed and passion" in the game.

From electric vehicles to industrial automation, to household appliances, PMSM motors continue to revolutionize the way we convert electrical energy into mechanical motion. Their combination of high efficiency, precise control and reliability makes them an indispensable technology in our increasingly electrified world. As research and development continues, we can expect to see more impressive applications and performance improvements in the coming years.

Ready to choose the most suitable power solution for your project? In-depth understanding of PMSM motors will be your first step in making an informed decision.

Ready to Explore PMSM Motor Solutions?

Discover how PMSM motors can transform your applications with superior efficiency and performance

Request Technical ConsultationGet expert advice on integrating PMSM technology into your projects