As electric vehicle (EV) technology continues to evolve, “In-wheel Electric Motor” is becoming the focus of more and more modders and engineers. This design of integrating the electric motor directly into the wheels not only greatly simplifies the structure of the drive system, but also gives the vehicle better responsiveness and modular modification potential.

If you are considering electric vehicle conversion or looking for an efficient, compact, and futuristic power solution, this article will give you a comprehensive understanding of the in-wheel electric motor car conversion kits currently available on the market, and provide you with model selection suggestions, technical background, and mainstream brand analysis

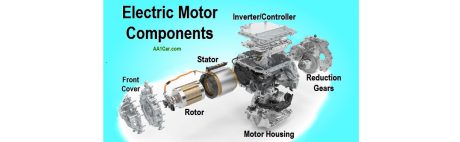

What Are In-Wheel Motors?

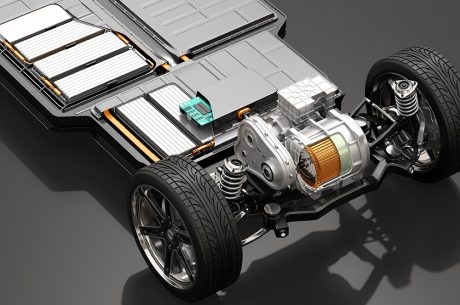

In-wheel motors integrate electric propulsion directly into wheel hubs, eliminating driveshafts and differentials. Key advantages:

- ✅ Direct drive: Reduced energy loss

- ✅ Weight distribution: Enables 4WD torque vectoring

- ✅ Space-saving: No transmission needed

- ✅ Modular design: Ideal for compact vehicles

Challenges include unsprung weight management and thermal control.

Ideal Conversion Applications

- 🏙️ City cars: Smart, Fiat 500, trikes

- 🕰️ Classic restomods: Minimal chassis modification

- 📦 Urban logistics: Piaggio Ape, Tuk Tuks

- 🤖 Specialty vehicles: Autonomous platforms, agri-shuttles

- 🏍️ E-mobility: Quad bikes, heavy-duty scooters

Top In-Wheel Motor Kits Compared

| Brand | Power Per Wheel | Peak Torque | Best For |

|---|---|---|---|

| Protean (UK) | 75-100kW | 1250Nm | Luxury cars/SUVs |

| Elaphe (Slovenia) | 30-85kW | 500-1000Nm | Compact EVs |

| ZM Motor (China) | 8-20kW | 120-350Nm | Low-speed logistics |

| CMVTE (China) | 10-50kW* | 150-700Nm | Custom classic cars |

*Customizable output

Pre-Conversion Checklist

- Power requirements: Single-wheel vs 4WD configuration

- Compatibility check: Wheel size/suspension clearance

- Controller matching: Voltage/current alignment

- Legal compliance: Regional certification requirements

- Technical support: Documentation & debugging access

Real-World Conversion Examples

Case 1: Classic Mini 4WD Conversion

German restomod using Elaphe motors + 400V battery. Retained original structure with reinforced suspension.

Case 2: Piaggio Ape Delivery Trike

Southeast Asian logistics solution with ZM motors (12kW/wheel). Achieves 80km range for daily urban use.

FAQ

Q: Does unsprung weight affect handling?

A: Minimal impact at city speeds. High-end kits include suspension optimization.

Q: Are in-wheel motors less efficient?

A: Actually more efficient at low speeds due to direct drive. Controller quality affects overall consumption.

Q: Can beginners attempt this conversion?

A: Recommended for builders with EV control experience or professional support.

Conclusion: The Future of EV Drivetrains?

Despite weight and cost challenges, in-wheel motors represent the next evolution in EV design – offering unprecedented packaging flexibility and control precision. For builders seeking minimalist drivetrains and cutting-edge performance, these kits unlock revolutionary possibilities.

When selecting your solution, prioritize:

- 🔧 Technical capability match

- 📐 Vehicle compatibility

- 🌐 Regional support network