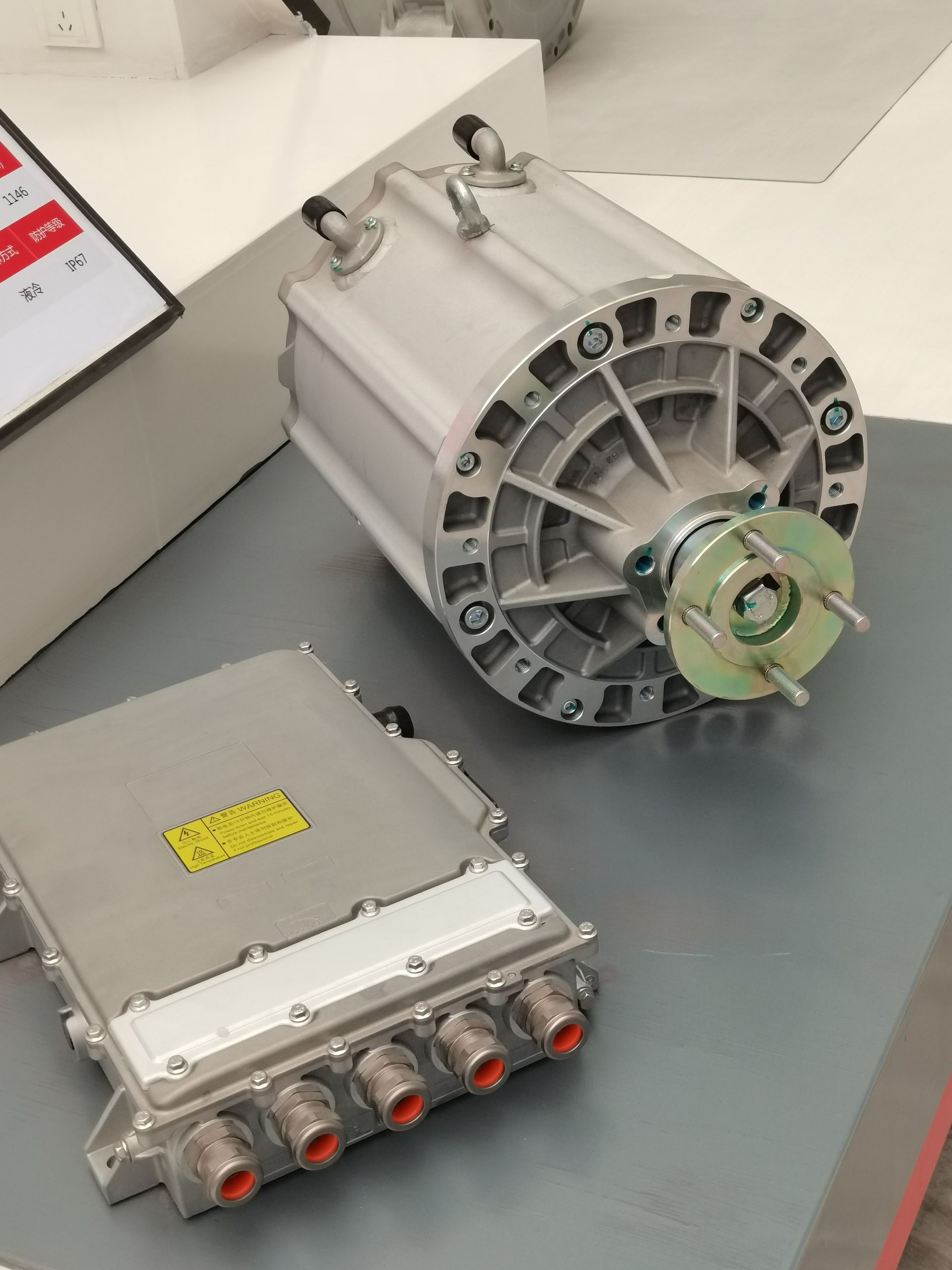

In recent years, the electric vehicle market has seen continuous growth in demand for motors with built-in liquid cooling systems. Currently, CMVTE's liquid-cooled motors are primarily based on permanent magnet synchronous motor technology, with rated power all above 15kW. The larger the motor power, the more critical the integrated liquid cooling system becomes. Especially for motors with power exceeding 30kW, liquid cooling has become the standard configuration.

With the continuous development of electric vehicle technology, liquid cooling technology represents a significant advancement in thermal management systems. This technology not only enhances performance but also extends the motor's service life, making it an indispensable component in modern electric vehicle design.

Table of Contents

ToggleLiquid Cooling Motor: Injecting "Water of Life" for Electric Vehicles

As electric vehicles become increasingly popular, we not only focus on their range and charging speed but also on a crucial yet often overlooked aspect: motor temperature management. In this temperature control system, the liquid-cooled motor quietly plays the role of the "temperature hero" for electric vehicles.

Motors Also Need "Rest" - The Challenge of Temperature Control

Imagine driving on a hot summer day with the air conditioning set to a comfortable temperature, but the engine starts to overheat and overall performance begins to decline. This phenomenon is common in traditional cars because engines consume a lot of energy and generate heat. For electric vehicles, although the motor doesn't have an exhaust system like an internal combustion engine, it still generates heat, especially during high-speed driving or prolonged acceleration.

This is where the liquid-cooled motor comes into play, like giving the electric vehicle a "glass of ice water." The liquid circulating through the motor absorbs internal heat, helping it maintain an ideal operating temperature. Just as people need cold drinks in hot weather, the motor needs this "comfortable environment" to achieve optimal operating conditions.

The "Secret" of Liquid Cooling Motors

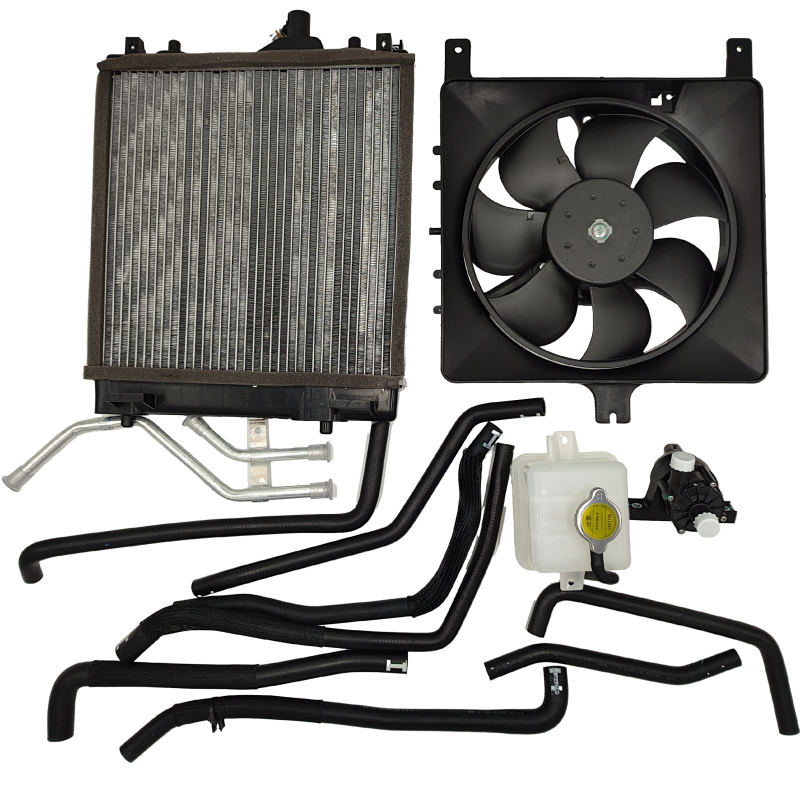

The working principle of liquid-cooled motors is both precise and efficient. When the motor operates and generates heat, this heat is quickly absorbed by specially formulated coolant. The coolant flows through precisely designed channels around the motor, absorbs heat, then moves to the radiator where the heat is dissipated, and then returns to the motor. This process completes a continuous cycle, maintaining the motor within the optimal temperature range of 60-80°C.

This system ensures the motor operates stably under prolonged high-load conditions. Just as long-distance runners need hydration and cooling, motors need liquid cooling to avoid overheating, which can affect efficiency and cause permanent damage to sensitive components.

Core Advantages of Liquid Cooling Motors

The introduction of liquid-cooled motors has brought multiple practical benefits to electric vehicles, enhancing performance and improving user experience.

Higher Efficiency

The heat dissipation effect of liquid cooling systems is significantly better, keeping the motor in optimal working condition. This means that even during prolonged high-speed driving or intense acceleration, the motor can continuously provide power without performance degradation due to overheating. Compared with air-cooled systems, efficiency typically increases by 15-20%.

Extended Service Life

Prolonged high temperatures are harmful to any machinery, and motors are no exception. Liquid-cooled motors help maintain stable temperatures, preventing heat-related damage, and can extend motor life by 30-50% compared to air-cooled alternatives. This directly translates to lower long-term ownership costs.

Enhanced Driving Experience

Another key advantage of liquid-cooled motors is their quiet operation. Compared to the noise generated by air-cooled motors, liquid cooling systems are significantly quieter, allowing for a more peaceful and enjoyable driving experience. Liquid cooling systems typically achieve 5-10 decibels of noise reduction.

Adaptation to Extreme Conditions

For users living in extreme climate conditions, liquid-cooled motors provide additional reliability. Whether in extremely hot or cold environments, the liquid cooling system ensures the motor continues to operate optimally, enabling electric vehicles to perform excellently in any environment from desert heat to arctic cold.

Higher Power Density

Through effective thermal management, liquid-cooled motors can achieve higher power density, outputting more power in the same volume, which is particularly important for space-constrained electric vehicle designs.

Cooling System Comparative Analysis

Understanding the differences between different cooling technologies helps explain why liquid cooling has become the preferred solution for high-performance electric vehicles.

| Characteristic | Air-Cooled System | Liquid-Cooled System |

|---|---|---|

| Cooling Efficiency | Medium | High |

| Noise Level | Higher | Lower |

| System Complexity | Low | High |

| Maintenance Requirements | Low | Medium |

| Cost | Lower | Higher |

| Weight | Lighter | Heavier |

| Optimal Application Scenarios | Low-power applications | High-performance vehicles, continuous high-load conditions |

Challenges Facing Liquid Cooling Motors

Although liquid-cooled motors offer many benefits, there are still some challenges to consider when evaluating this technology for electric vehicles.

Higher Cost

Liquid cooling systems are more expensive than traditional air-cooled systems because they require additional components such as coolant pipes, pumps, radiators, and reservoirs, which increases manufacturing and maintenance costs. Initial costs may be 20-30% higher than equivalent air-cooled systems.

Complex Maintenance

Maintenance of liquid cooling systems is more complex, requiring regular checks of coolant levels, quality, and system integrity to ensure there are no leaks or malfunctions. Repairs usually require professional knowledge and may increase service costs over the vehicle's lifetime.

Additional Weight

Liquid cooling systems tend to be heavier than air-cooled systems, which adds to the weight of electric vehicles. While this may not be a problem for high-performance electric vehicles, it is a consideration for models aiming for extreme lightweight design, as every kilogram affects efficiency.

Potential Leakage Risk

Although modern liquid cooling systems are precisely designed, there is still a potential risk of leakage, which could lead to reduced cooling effectiveness or even damage to motor components.

Application Scenarios and Future Development Trends

Liquid cooling technology is particularly beneficial in high-performance electric vehicles, commercial electric vehicles, and applications where motors need to operate continuously under heavy loads. As battery technology advances and power density increases, the importance of efficient thermal management systems will only grow.

Future developments may include:

- More Compact Cooling Systems: Providing better cooling effects in limited spaces

- Advanced Coolants: Advanced coolants with higher heat capacity

- Integrated Thermal Management: Combining motor, battery, and power electronics cooling into a single efficient system

- Intelligent Temperature Control: AI-based predictive thermal management systems that optimize cooling strategies based on driving patterns

CMVTE Liquid Cooling Motor Solutions

As a professional provider in the field of electric vehicle conversion, CMVTE offers comprehensive liquid cooling motor solutions to meet the needs of different application scenarios:

- Wide Power Range: Full range of liquid-cooled motors from 15kW to 350kW

- Customized Design: Providing customized cooling solutions based on different vehicle models and performance requirements

- Complete Kit Supply: Providing complete conversion kits including motors, cooling systems, and controllers

- Professional Technical Support: Full-process technical services from design to installation

Conclusion: The Thermal Management Guardian of Electric Vehicles

Liquid-cooled motors are like the "temperature regulation system" of electric vehicles, ensuring the motor operates at its optimal temperature. This technology improves motor performance, extends the service life of electric vehicles, and provides a more comfortable and safer driving experience. As electric vehicles continue to develop towards higher power density and greater performance requirements, liquid cooling will play an increasingly important role in thermal management.

So, next time you enjoy a smooth and effortless journey in an electric vehicle, take a moment to thank this "temperature hero" - the liquid cooling system, which works silently to maintain optimal performance and reliability throughout the journey.

Ready to choose the most suitable liquid cooling solution for your electric vehicle project? The CMVTE professional team is always ready to provide technical consultation and customized solutions.

Need Professional Liquid Cooling Solutions?

Our liquid-cooled motor systems provide reliable thermal management for high-performance EV applications

Request Technical ConsultationGet expert advice on integrating liquid cooling technology into your EV projects