When you turn the key or press the start button and the "READY" or "OK" indicator lights up on the dashboard, have you ever wondered about the precise "handshake protocol" related to safety being executed inside the electric vehicle?

This seemingly simple startup process actually conceals the critical safety logic of the high-voltage system—pre-charge control.

Table of Contents

TogglePre-Charging: The Safety Gatekeeper for High-Voltage Power-Up

Imagine the traction battery as an energy reservoir waiting to be activated, while the capacitors inside the motor controller are like a huge "empty cup."

If high voltage is directly connected, the instantaneous inrush current would be like floodwaters impacting an empty cup, enough to destroy the high-voltage circuit.

Engineers use pre-charge resistors as "buffers" to gently inject current into the capacitors, only connecting the main circuit after the voltage stabilizes.

This millisecond-level precise operation is a key barrier to avoid thousands of amperes of short-circuit current, and it's also the invisible guardian protecting core components like batteries and motors.

1. Detailed Explanation of EV High-Voltage Power-Up Process

After the vehicle starts, the low-voltage system is first awakened and self-checked. High-voltage power-up is only permitted after confirming the system is fault-free.

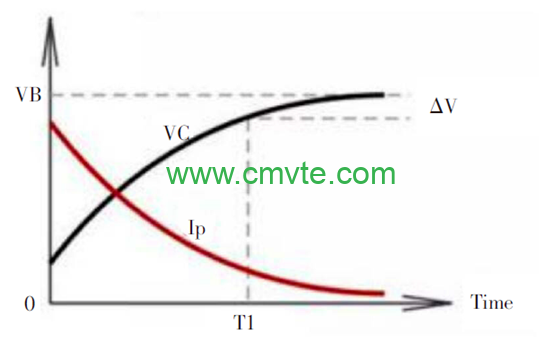

Battery Management System (BMS) controls the negative contactor (K-) and pre-charge contactor (Kp) to close, performing pre-charging on the bus capacitor C in the motor controller. Pre-charging is completed when the voltage difference between the bus capacitor voltage VC and the traction battery voltage VB reaches a specific value.

When BMS detects pre-charging is complete, it controls the positive contactor (K+) to close, formally outputting high voltage to external loads, then controls the pre-charge contactor (Kp) to open. At this point, the dashboard displays the OK or READY light, indicating high-voltage power-up is complete.

During this period, BMS monitors the system status in real-time. If serious faults such as insulation or high-voltage interlock issues occur, it will control K+ and K- to open, stopping high-voltage output.

2. In-depth Analysis of Pre-Charge Control Logic

When an EV powers up its high-voltage system, pre-charging must be performed first to pre-charge the bus capacitors in the motor controller. This is because in the high-voltage circuit, the bus capacitor is in parallel with the traction battery. When the traction battery outputs high voltage, it charges the capacitor, and the capacitor's resistance is almost zero at the moment of charging, equivalent to a conductive state.

If the negative contactor (K-) and positive contactor (K+) are directly closed during high-voltage power-up, it's equivalent to directly connecting the positive and negative terminals of the traction battery. At this point, the traction battery is effectively short-circuited, and the instantaneous high current generated in the circuit can damage high-voltage lines and components.

Therefore, during high-voltage power-up, the negative contactor (K-) and pre-charge contactor (Kp) must be closed first, allowing high voltage to charge the bus capacitor through the pre-charge circuit.

Since the pre-charge circuit has a pre-charge resistor (R) in series, according to Ohm's Law I=U/R, the current during pre-charging is reduced to a range that the high-voltage circuit can withstand, using the current-limiting effect of the pre-charge resistor to protect the high-voltage circuit and components.

When the voltage difference between the bus capacitor voltage VC and the traction battery voltage VB is sufficiently small and reaches the set value (for example, mainstream models in 2025 set ΔV ≤ 25V or ΔV ≤ VB × 5%), BMS determines that pre-charging is complete, controls the positive contactor (K+) to close, then opens the pre-charge contactor (Kp). The vehicle normally enters the high-voltage powered state.

3. Function and Necessity Analysis of Bus Capacitors

From the above analysis, it can be seen that pre-charging during high-voltage power-up is mainly aimed at the capacitors in the motor controller, protecting the high-voltage circuit and components through pre-charging.

Why are capacitors installed in motor controllers?

There are many high-voltage electrical devices in the high-voltage circuit, with the motor drive system being the most important one. The motor controller converts high-voltage DC to three-phase AC to drive the motor. The motor controller's control of the drive motor needs real-time adjustment according to the vehicle's actual driving requirements, so the power consumed by the motor controller varies under different driving conditions and changes constantly.

This causes significant fluctuations in the traction battery bus voltage, affecting the working stability of high-voltage electrical devices, which in turn affects the EV's working state and driving experience.

Therefore, the most important function of installing capacitors in motor controllers is to balance voltage fluctuations. When power consumption increases sharply, the capacitor discharges to provide auxiliary power; when power consumption decreases, it absorbs bus voltage to store energy.

4. Contactor Structure and Working Principle Analysis

Contactors in new energy vehicles are essentially circuit control switches with protective properties, used to control the connection and disconnection of the traction battery charge/discharge circuit. They are core components of the new energy vehicle power system. To avoid arc erosion of contacts during high-voltage circuit connection/disconnection, they generally have a fully sealed structure with the inner cavity filled with inert gas.

The working principle of contactors is basically the same as ordinary relays.

In the initial state, high-voltage contacts are normally open, and the high-voltage circuit is disconnected; when the coil is energized, it generates a magnetic field that attracts the connection plate, the contacts connect, and the high-voltage circuit is connected.

This uses 12V low voltage in the coil to control the high voltage in the high-voltage contact circuit.

5. 2025 Pre-Charging Technology Development Trends

As 800V high-voltage platforms gradually become mainstream in high-end electric models in 2025, pre-charging technology also faces new challenges and opportunities:

Faster Pre-Charging Speed

Reduced from traditional 100-300 milliseconds to within 50 milliseconds

More Precise Voltage Control

Voltage difference detection accuracy improved from traditional 5% to within 2%

Intelligent Pre-Charge Management

AI algorithm-based prediction of capacitor state, optimizing pre-charge parameters

Additional trends include:

- Adaptive Pre-Charge: Systems that adjust parameters based on temperature and component age

- Predictive Maintenance: Monitoring pre-charge performance to predict component failures

- Ultra-Fast Charging Compatibility: Enhanced pre-charge systems for rapid DC charging

- Solid-State Contactor Technology: Replacing traditional contactors with solid-state switches

Practical Guide to Fault Diagnosis

In diagnosing faults where EVs cannot normally power up the high-voltage system, special attention should be paid to the dynamic data stream of the pre-charge status. If the data shows "no pre-charge" or "pre-charge failure," it's necessary to detect the power supply and control signal of the pre-charge contactor coil, ultimately confirming and eliminating the fault.

Common Pre-Charge Faults

- Pre-charge resistor failure

- Contactor coil malfunction

- Capacitor leakage or short circuit

- BMS communication errors

Diagnostic Steps

- Check diagnostic trouble codes

- Monitor pre-charge voltage progression

- Test contactor operation

- Measure resistor values

- Verify BMS functionality

Conclusion

Although the pre-charge circuit is small, it is the cornerstone of the safe operation of the EV high-voltage system. With the new generation of intelligent pre-charge modules launched by CMVTE in 2025, the high-voltage power-up process of electric vehicles will become safer, more efficient, and more reliable.

The evolution of pre-charge technology represents a critical advancement in EV safety systems, ensuring that as battery voltages increase and charging speeds accelerate, the fundamental safety protocols keep pace with technological progress.

Learn More About EV Safety Systems

Get in-depth technical documentation and expert guidance on EV high-voltage systems and safety protocols.

Download Technical White Paper