In the cab of a modern agricultural vehicle, the display is the mission control center. When converting a tractor or sprayer to electric power, this becomes exponentially more true. The right Smart LCD Display transforms from a simple monitor into the vital interface between the operator and the entirely new electric drivetrain. It’s the component that translates complex data into actionable insight, ensuring not only peak performance but also safety and operational confidence. Choosing the perfect display is about selecting the brain and nervous system for your converted machine.

Forget consumer-grade tablets or automotive infotainment screens. The agricultural environment and the unique demands of an EV conversion require a purpose-built solution. Here are the critical factors to consider when selecting the perfect Smart LCD Display for your farming EV.

1. The Non-Negotiables: Built for the Brutal Farm Environment

First and foremost, the display must be engineered to survive where it will live.

-

Sunlight-Readable Brilliance: A display must be visible in direct midday sun, not just in a shaded cab. Look for a high-brightness rating (1000 nits or higher) and an optical-bonded screen. Optical bonding laminates the touch layer directly to the LCD, eliminating the air gap that causes internal reflection and glare. This is critical for clarity and reducing eye strain during long hours.

-

Extreme Ruggedness: It must withstand constant vibration, shock from rough terrain, wide temperature swings (-30°C to 70°C), and humidity. A fully metal housing, conformal-coated internal electronics, and a high IP rating (IP65 minimum, IP69K ideal) for dust and high-pressure washdown protection are essential.

-

Glove-Friendly Touch: Operators wear work gloves. The display must feature a robust capacitive or superior projected capacitive (PCAP) touchscreen that registers input through thick gloves, or be complemented by physical, sealed menu buttons for critical functions.

2. The Core Intelligence: Software and Integration Capabilities

The hardware is just the shell; the software and communication capabilities define its true utility for an EV conversion.

-

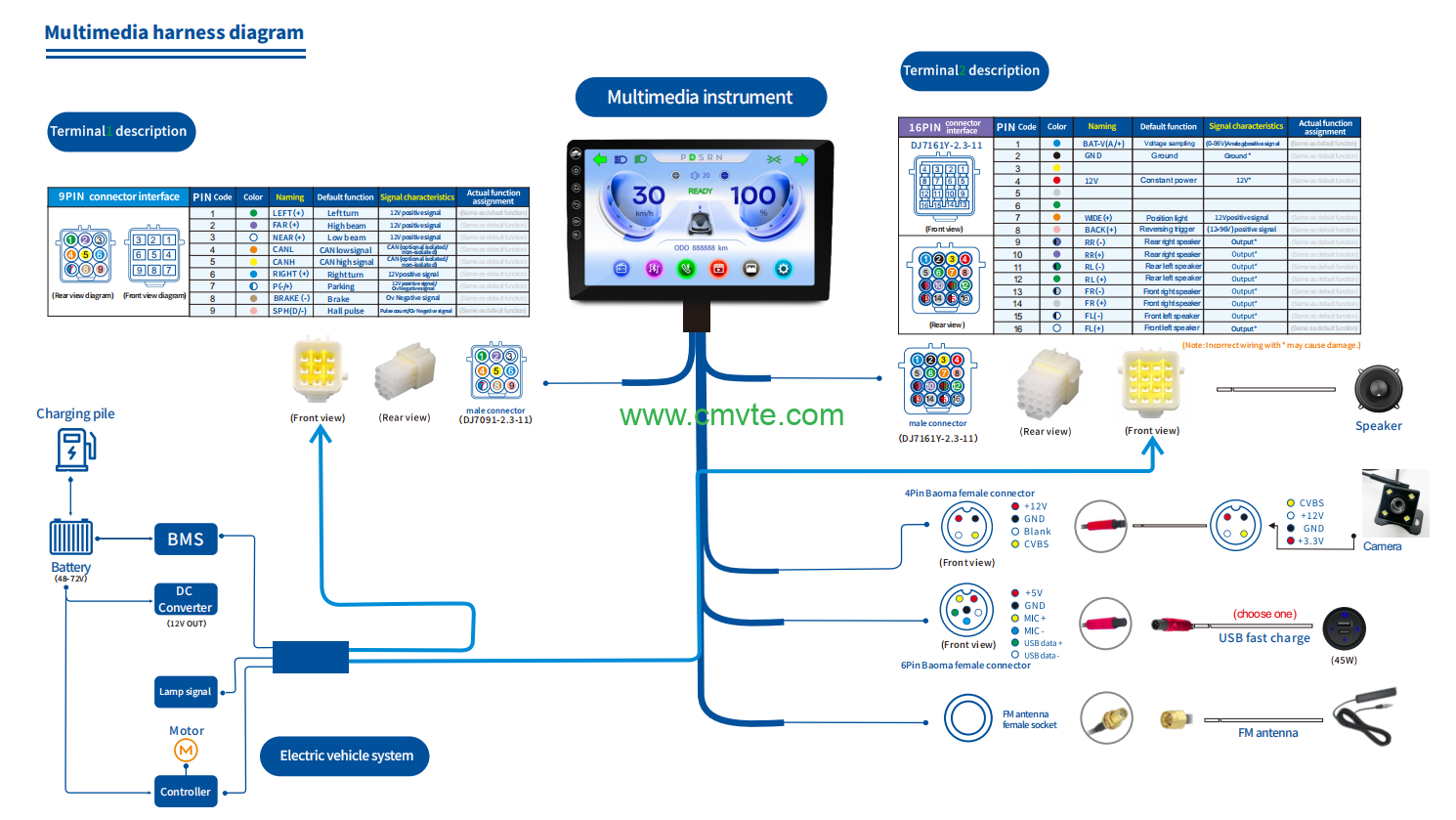

Native CAN Bus Integration: This is the single most important feature. The display must act as a CAN Bus gateway, capable of reading and interpreting the J1939 and custom CAN messages from your entire system. It should natively display key parameters without requiring a separate dongle or complex middleware.

-

Customizable EV-Specific Dashboards: It must move beyond a simple speedometer. You need to create tailored views showing:

-

Traction Battery: State of Charge (SOC), State of Health (SOH), pack voltage, current, and individual cell/minimum temperatures.

-

Motor & Controller: Real-time power (kW), torque (Nm), temperature, and RPM.

-

System Health: Status of the DC-DC converter, insulation monitoring device (IMD) alerts, and contactor state.

-

Efficiency Metrics: Instantaneous and average kWh per hectare/hour, regenerated energy, and remaining operating time estimates.

-

-

Diagnostic & Logging Power: The display should provide advanced diagnostic screens to view fault codes from all connected devices (motor controller, BMS, etc.) and have built-in data logging to record operational data. This is invaluable for troubleshooting, performance tuning, and validating duty cycles for future design improvements.

3. Matching the Display to the Machine’s Role

-

For Medium-Duty Tractors (30-60kW): Focus shifts to clarity, simplicity, and essential data. A 7 to 10-inch display is often ideal. The primary screen should prominently show SOC, motor power/temperature, and a clear fault indicator. The priority is giving the operator an intuitive, at-a-glance understanding of system status without information overload during routine tasks like tilling or planting. Ease of customization for different implements is a major plus.

-

For Heavy-Duty Tractors (70-100kW+): These complex machines demand comprehensive data visualization and multi-tasking. A larger 10 to 15-inch display is recommended. It must support split-screen views—showing drivetrain vitals on one side and implement control (e.g., hydraulic flow rates, planter metrics) on the other. Support for ISO 11783 (ISOBUS) compatibility becomes crucial here, allowing the single display to also act as the Virtual Terminal for smart implements. Processing power and screen real estate are key to managing the high data flow.

4. Future-Proofing and Safety

-

Connectivity and Expansion: Look for displays with Wi-Fi, Ethernet, or 4G/5G modules for remote diagnostics, wireless data export, and potential over-the-air (OTA) updates. This connects the machine to the wider farm management system.

-

Safety as a Priority: The display must be configured to provide unmissable visual and audible alarms for critical faults: low SOC, high-temperature warnings, or insulation faults. The ability to quickly silence non-critical alerts while maintaining visibility of major ones is a subtle but important feature in a busy operational environment.

The Bottom Line: Your Window into Electrification

The perfect Smart LCD Display is more than a screen; it is the integrated human-machine interface (HMI) that demystifies your electric conversion. It builds operator trust by replacing the familiar roar of a diesel engine with clear, reliable data. It turns raw electrical signals into a story about performance, efficiency, and health.

Investing in a display designed for ruggedness, deep system integration, and customizable data presentation is not an optional accessory—it is the cornerstone of a professional, safe, and user-friendly conversion. It ensures that the operator is informed, in control, and can harness the full potential of electric drive, making the sophisticated technology beneath the hood both visible and manageable from the seat of the tractor.