When we’re converting a conventional internal-combustion vehicle into an electric vehicle (EV), one of the most critical decisions is selecting the appropriate electric motor. This decision influences performance, cost, packaging, and how the car “feels” to drive. Based on CMVTE practical experience, here’s a guide to help you choose the best electric motor for car conversion.

1. Think in terms of torque, not just kilowatts

A common mistake is to pick a motor purely on its kW or horsepower rating, by comparing it to the original ICE engine.

Electric motors deliver their maximum torque at zero rpm and maintain strong torque well through their rpm range.

Therefore:

- Identify the torque (Nm) of the original vehicle – or a target value slightly higher.

- Choose a motor whose peak torque at zero rpm is at least equal.

- The advantage: instant response and strong acceleration from standstill, which is one of the major joys of EV conversion.

2. Voltage, current & system design all matter

It is impossible to choose a motor in isolation.

- Voltage (V): Higher voltage allows lower current for the same power (P = V×I), which means smaller conductors, potentially less heat loss, and better efficiency.

- Current (I): High current at low voltage means heavier cables, bigger contactors, more cost and complexity.

- Battery pack compatibility: Space, weight, and mounting of the battery pack must match the motor choice. For instance, a motor designed for 750 V is likely overkill (and expensive) for a small conversion.

- RPM and gearing: If the motor rpm is very high, your gearbox or final drive must match or you lose efficiency or torque at the wheels.

- Thermal/cooling demands: High power motors often require cooling systems.

3. Vehicle size, weight and performance target

Another key insight: “The properties of the vehicle such as size, weight and aerodynamics are crucial characteristics that will determine speed, torque and power requirements of the electric motor.”

Before selecting a motor:

- Estimate the curb weight + battery weight of the converted vehicle.

- Decide your target: Do you want brisk acceleration, or merely cruise capability? For a small urban vehicle you may not need 300 kW.

- Consider continuous vs peak power: If you intend motorway cruising at 140 mph, you need high continuous power (e.g., 160 kW) — for 70 mph a 60 kW motor may suffice.

4. Packaging, budget & practicalities

Even the “best” motor on paper becomes a poor choice if it cannot physically fit the car or exceed budget. Key practical considerations:

- Physical size & weight of the motor, gearbox adaptation (if retaining original transmission)

- Batteries: how many, where to place, structural modifications

- Cost: Lower-voltage systems (say 100-150 V) are cheaper in components (connectors, wiring, etc) than ultra-high-voltage systems.

- Experience: A tried and tested motor with a strong aftermarket support and conversion community may reduce risk and hidden costs.

5. Recommendation workflow

Putting all this together, here’s a recommended workflow for selecting the best motor:

- Define your vehicle and performance target (e.g., “mid-size sedan, 0-60 mph in ~6 s, cruising at 70 mph”)

- Estimate required torque at zero rpm (based on weight, desired acceleration)

- Choose voltage band based on your battery pack size, budget, and packaging (100-150 V for smaller/light vehicles; 300-400 V for larger/heavy vehicles)

- Select candidate motors whose torque meets/exceeds step 2, whose rpm and gearing work with your drivetrain, and whose voltage aligns with step 3

- Check physical fit, adaptation complexity, thermal management, support/documentation, cost

- Iterate: if one parameter (battery pack size or voltage) changes, the others must adapt.

6. Example motors (for reference)

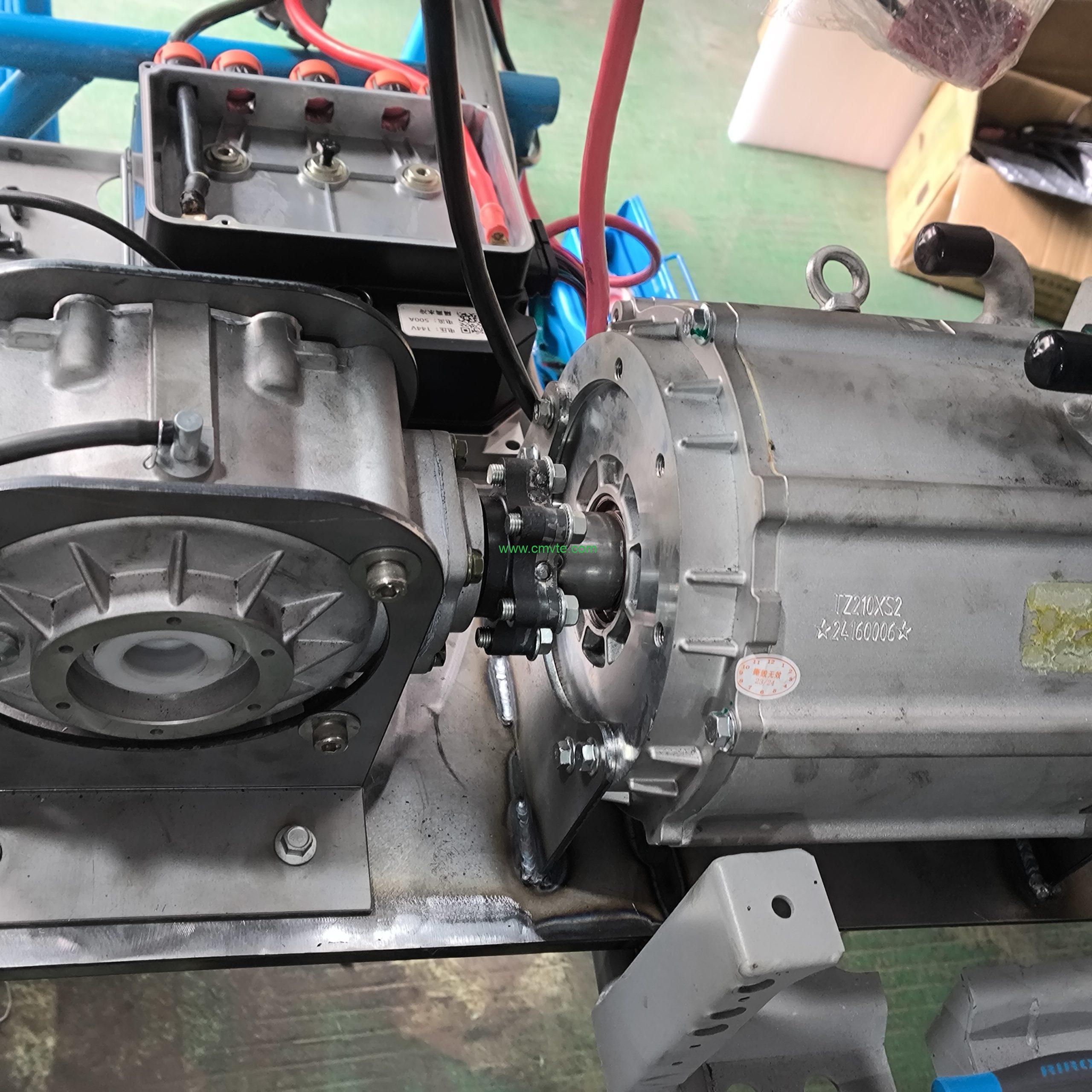

- On CMVTE website, 144 V 40KW version motor as a first choice for the conversion of 1 ton sedan”. It produces 250 Nm peak torque and 65 kW of peak power.

- By contrast, a high‐performance EV motor from a vehicle like the Tesla Model S (350 V, ~660 Nm torque and ~375 kW) requires far more battery capacity and supporting systems.

These show the spectrum: pick the right scale for your project.

7. Conclusion

The best electric motor for your car conversion is the one that matches your vehicle, car performance expectations, and your budget — not necessarily the one with the highest spec sheet. If you are torn with which motor type/power of motor to choose, please make inquiries at CMVTE, we will serve you around the clock!