In the world of precision manufacturing and industrial automation, permanent magnet (PM) motors are ubiquitous. They power our robots, CNC machine tools, and electric vehicles. However, even the most efficient PM motors face a common challenge—cogging torque. This subtle force, generated when the motor windings are de-energized, is nonetheless a critical factor affecting motor performance.

What is Cogging Torque?

Cogging torque, also known as detent torque, is a periodic torque produced by the interaction between the permanent magnets and the stator core of a PM motor when the windings are not energized. Simply put, it is caused by the tangential component of the force between the permanent magnets and the armature teeth.

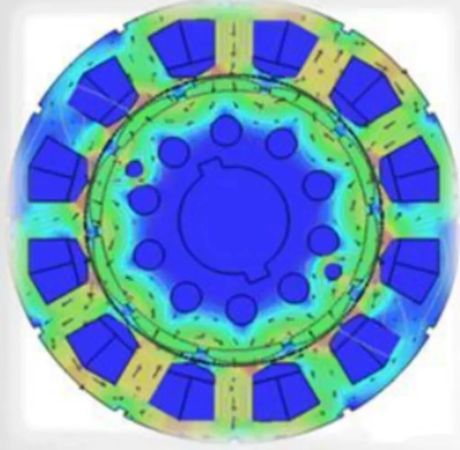

When the motor rotor rotates, the magnetic permeability within a small range of the stator slots corresponding to both sides of the permanent magnets changes significantly, leading to variations in magnetic field energy storage and thus generating cogging torque. From an energy perspective, this phenomenon can be seen as a result of magnetic field lines closing along the path with the least magnetic reluctance when the magnetic reluctance distribution in the magnetic circuit is uneven—a principle known as the “minimum magnetic reluctance principle”.

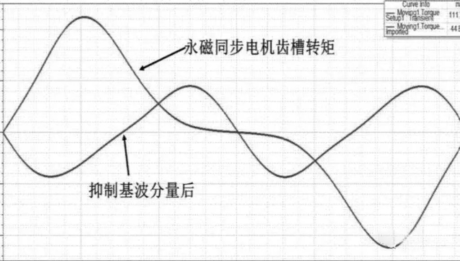

Diagram of Cogging Torque

The Hazards of Cogging Torque Should Not Be Underestimated

The presence of cogging torque causes torque ripple in PM motors, which in turn leads to speed fluctuations. This torque ripple can induce vibration and noise in the motor—when the frequency of the pulsating torque matches the resonant frequency of the armature current, resonance occurs, amplifying the vibration and noise caused by cogging torque.

In variable-speed drives, when the frequency of the torque ripple coincides with the mechanical resonant frequency of the stator or rotor, the vibration and noise generated by cogging torque will be amplified. These issues can seriously affect the positioning accuracy and servo performance of the motor, especially when operating at low speeds.

Under normal circumstances, cogging torque accounts for only 5%-10% of the rated torque. However, in high-precision applications, it is required to be controlled within 1%-2%.

How to Mitigate Cogging Torque?

Scholars have proposed a variety of effective solutions to address cogging torque, which can be primarily categorized into three aspects: overall motor design optimization, stator-side improvements, and rotor-side modifications.

1. Overall Motor Design Optimization

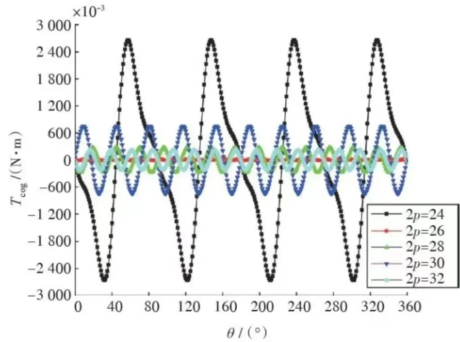

The use of fractional-slot windings is an effective overall design method. By selecting a combination of stator slot number (Z) and rotor pole number (2p) with a large least common multiple (LCM), the amplitude of cogging torque can be reduced.

In fractional-slot winding motors, the magnetic field positions of each slot opening are different, so the phases of the cogging torque generated by each slot also differ. The superposition result not only increases the number of cycles of the fundamental cogging torque but may also produce a mutual compensation effect.

For example, with the same 9-slot stator lamination, the peak cogging torque is 30 mNm when matched with a 6-pole rotor, while it is only 2 mNm when matched with an 8-pole rotor. This difference stems from the different LCM values of Z and 2p (18 and 72, respectively).

Cogging Torque with Different Pole Numbers

2. Stator-Side Improvement Measures

Stator skewing is one of the most effective and widely used methods to suppress cogging torque ripple. This method is mainly applied to motors with a large number of stator slots and long axial length. Practice has proven that stator skewing can reduce the amplitude of all harmonic components of the motor’s electromagnetic torque.

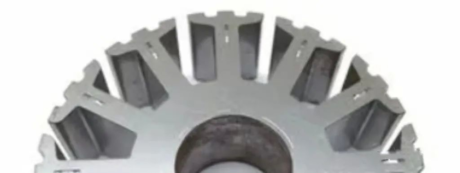

Adding auxiliary slots on stator teeth can increase the number of cycles of the fundamental cogging torque. The cogging torque caused by the auxiliary slots compensates for the cogging torque generated by the original slot openings. Studies have shown that for a 4-pole 6-slot motor, when two auxiliary slots are added to the stator, the cogging torque can be reduced from 1.04 Nm to 0.2 Nm.

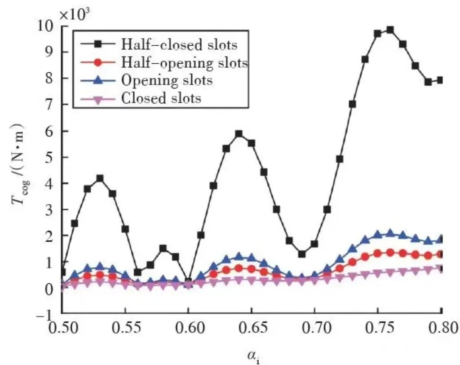

Slot opening width optimization is also an important stator-side improvement measure. For fractional-slot motors such as 12-slot 14-pole motors, when the slot opening width is 3.45 mm, the cogging torque is approximately 6% of that when the slot opening width is 2 mm. For fractional-slot motors, a smaller slot opening width is not always better; instead, there exists an optimal slot opening width to choose from.

Cogging Torque with Different Slot Types

3. Rotor-Side Modification Methods

Optimizing the pole arc coefficient can effectively reduce cogging torque. The pole arc coefficient α refers to the ratio of the pole arc width to the pole pitch. For fractional-slot motors such as 9-slot 8-pole motors, the cogging torque is relatively small when the pole arc coefficients are 0.89, 0.78, or 0.67.

Adopting an non-uniform air gap is another rotor-side modification method. By designing an unequal air gap (smaller air gap at the center of the magnet and larger air gap at the pole tips), the air gap flux density distribution under the magnet can be made closer to a sine wave, thereby reducing cogging torque.

Rotor Structure with Non-Uniform Air Gap

Rotor skewing operates on a similar principle to stator skewing, but in terms of manufacturing process, segmental rotor displacement is usually used to approximate skewing. Studies have shown that when the number of rotor segments reaches 5, cogging torque can be completely negligible.

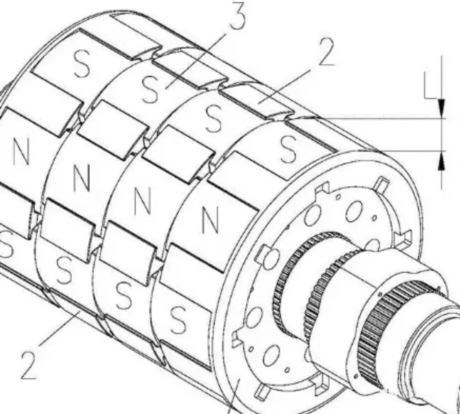

Rotor Pole Displacement Structure

Pole shifting involves shifting the poles from their original uniformly distributed positions to a circumferential offset. This is equivalent to having 2p segmental poles within one fundamental cogging torque cycle, which can effectively mitigate cogging torque. For example, for a 4-pole 24-slot motor, this method can reduce the cogging torque from 0.2 Nm to 0.02 Nm.

Pole Shifting Structure

The principle of reducing cogging torque by adding auxiliary slots on stator teeth lies in increasing the number of cycles of the fundamental cogging torque. The cogging torque caused by the auxiliary slots compensates for the cogging torque generated by the original slot openings, thereby reducing the amplitude of the total cogging torque. Adding auxiliary slots also increases the equivalent air gap, which is also beneficial for reducing cogging torque. Literature indicates that for an 18-slot 12-pole motor, when two auxiliary slots are added to the stator, the number of cogging torque cycles triples and the cogging torque decreases by approximately three times. For a 4-pole 6-slot motor, adding two auxiliary slots reduces the cogging torque from 1.04 Nm to 0.2 Nm.

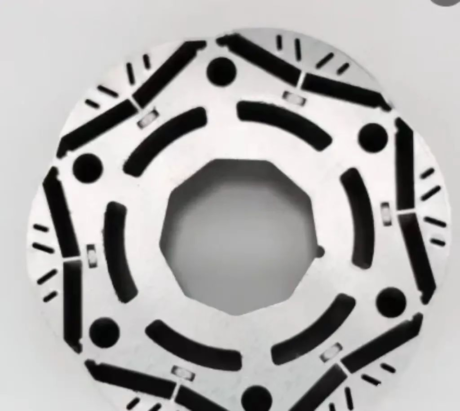

Stator Structure with Auxiliary Slots

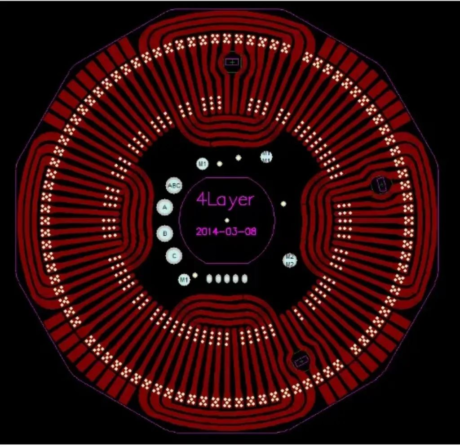

Ultimate Solution: Slotless Windings

The most thorough method is to adopt a slotless winding structure. This approach completely eliminates the root cause of cogging torque and was already applied in DC motors as early as the mid-1970s. However, the actual equivalent air gap of slotless motors is much larger than that of slotted motors, requiring a significantly higher excitation magnetomotive force.

Slotless Windings

With the rapid development of high-energy-product permanent magnet materials such as NdFeB, the practical application of slotless PM motors is gradually advancing, and they have now been used in some aerospace applications.

Conclusion

As an inherent characteristic of PM motors, cogging torque cannot be completely eliminated, but it can be mitigated to an acceptable range through the aforementioned methods. With the continuous expansion of motor application fields and the increasing demand for precision, in-depth research and control of cogging torque will become even more important.

In the future development of intelligent and precision-oriented industries, mastering the technology to suppress cogging torque will be a key step in improving motor performance. Whether for motor designers or users, understanding this “invisible force” means taking a significant step toward higher precision and efficiency.

As a consensus in the field of precision engineering goes: details determine success or failure. The precise control of cogging torque is an indispensable path for PM motors to achieve higher performance.