Have you ever stood by the charging pile, looking at the numbers beating on the screen, and wondering why the charging speed is sometimes fast and sometimes slow? Why is it always so long to go from 80% to 100%?

Behind this, it is not simply “the power is gradually full, the speed drops naturally”, but a set of precise engineering control art silently guarding your battery safety and health.

Understanding the constant current (CC) and constant voltage (CV) phases is the key to understanding how lithium batteries can be charged safely, quickly and healthily.

We can get to the bottom of it with a perfect metaphor for pouring water into a cup. Imagine charging your electric vehicle batteries, like “using a kettle and pouring water into a very delicate and expensive narrow-mouthed glass”.

· Kettle = Charging point (power supply)

· Water flow = charge current

· Water level in the cup = battery voltage

· Maximum capacity of the cup = voltage when the battery is fully charged (e.g. 4.2 V cell)

Your goal is to pour the water into the glass quickly and thoroughly, but never spill a drop (overcharge) or damage the glass with too much water.

The first stage: constant current charging- “full sprint irrigation”

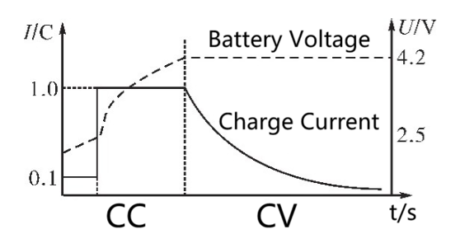

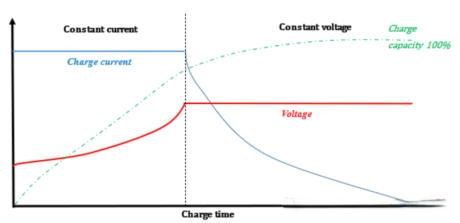

When the glass is still empty, the water level is low. To fill as quickly as possible, you tilt the kettle to a fixed, maximum safe angle, allowing a strong and steady stream of water (constant current) to flow continuously into the cup. This is similar to a low battery voltage when the battery SOC is low. The charging point will apply a “constant high current” (for example, the maximum current agreed between the vehicle and the charging point, such as 250A). It is obvious that:

- 1) The water level (voltage) rises rapidly: the battery voltage increases steadily and rapidly as the current continues to be injected;

- 2) This is the “main stage” of charging: about 80% of the battery’s power is charged quickly in this stage, so this is the key stage to pursue the charging speed.

At this stage, the charging pile is a “current source” whose task is to maintain a constant current. The vehicle’s battery management system (BMS) is like a supervisor, monitoring the voltage in real time to see when it is about to rise to the top.

Stage 2: Constant Voltage Charging- “Carefully Fill”

When the water level (voltage) rises very close to the cup mouth (full voltage), if you still maintain the large water flow just now, the inertia will cause the water to overflow the cup (overcharge), which is absolutely prohibited! At this time, you must immediately adjust the action: keep the height of the kettle mouth unchanged (that is, keep the “water pressure” of the cup mouth constant). Then gradually and slowly reduce the tilt angle of the kettle (reduce the current).

This is as if the charging phase is switched when the battery voltage rises to a preset end-of-charge voltage (e.g., 4.2 V/cell). The charging pile switches to the “constant voltage source” mode to maintain the voltage absolutely unchanged. This happens:

- 1) The voltage is “pinned” at the peak: it does not rise any more to prevent overvoltage damage.

- 2) The current begins to decay naturally: as the internal chemical potential of the battery gets closer to the externally applied voltage, the “push” to push the charge into the battery gets smaller and smaller, so the charging current will gradually decrease like a natural downward curve, and the BMS will continue to monitor the current.

- 3) This is the “leak repair phase” of charging: charging from 80% to 100%. The speed is getting slower and slower, like filling the last few corners. When the current is reduced to a very small preset value (for example, 0.05C, which is 5% of the maximum current), the BMS considers the battery to be “substantially full” and sends a command to stop charging completely. It’s like turning off the tap when you see that the water has become a trickle.

3 Why are these two phases needed?

Constant current (CC), speed, rapid irrigation with maximum safe water flow, shorten the charging time, and realize rapid energy supplement under the premise of safety. If an empty battery is charged with the maximum voltage at the beginning, a huge current will be generated, which may damage the battery in an instant.

Constant pressure (CV), safety and health, carefully filled. It can prevent overcharge, complete the final charge with small current, reduce the internal chemical stress of the battery, prolong the cycle life of the battery, and finally make each cell of the battery reach the real full charge state.

Constant current (CC) and constant voltage (CV) are the optimal charging curves determined by the physical and chemical characteristics of lithium ion batteries. It is not the patent of electric vehicle, and the batteries of your mobile phone and laptop follow the same rule. From the perspective of electrochemistry, electrical engineering and battery management system control, the constant current (CC) and constant voltage (CV) stages of battery charging are essentially the inevitable optimal control strategies to deal with the nonlinear internal resistance and diffusion kinetics limitations of lithium-ion batteries, and their fundamental purpose is to maximize the charging speed while strictly ensuring safety and minimizing battery aging. The following is a professional analysis from three levels:

3.1 Principle of electrochemistry: ion migration and electrode potential

1) Nature of battery voltage:

- The open circuit voltage is determined by the chemical potential difference between the positive and negative materials and is a monotonic function of the lithium ion concentration (SOC).

- The ohmic polarization voltage drop is caused by the internal resistance of the battery (including current collector, electrolyte, SEI film resistance, etc.) And is instantaneously related to the current.

- Electrochemical polarization and concentration polarization are related to the diffusion rate of ions on the electrode surface and in the bulk.

2) The dynamic process in the constant current stage. Applying a constant current at this stage is equivalent to “extracting” lithium ions from the positive electrode (e.g., NMC) through the electrolyte and “embedding” them into the negative electrode (e.g., graphite) at a constant rate. As the charge proceeds, the lithium ion concentration of the negative electrode increases and the positive electrode concentration decreases, resulting in a natural increase in the open circuit voltage. At the same time, the ohmic and polarization voltage drops at high current are significant. In order to ensure that the ions continue to migrate (i.e., maintain the current), the charging point must continuously increase the output voltage to overcome these voltage drops.

Therefore, the constant current phase is characterized by a constant current and a continuous linear/nonlinear voltage rise.

3) Thermodynamic equilibrium process at constant pressure stage:

When the voltage reaches the upper limit (such as 4.2 V/cell), this is a safety critical point. If the pressure continues to rise, the negative electrode potential will be driven beyond the thermodynamic stability window of graphite, leading to lithium evolution reaction (lithium ions directly obtain electrons on the surface of graphite and deposit as metal lithium), which is an irreversible and dangerous side reaction.

After switching to constant voltage mode, the potential difference between the two ends of the cell is fixed, and the “driving force” for ion migration reaches an upper limit. As the lithium concentration on the surface of the negative electrode approaches saturation, the resistance to the diffusion of ions from the electrolyte to the interior of the graphite bulk phase (concentration polarization) increases. In order to maintain a fixed terminal voltage, the current must naturally decay as the open-circuit voltage approaches, depending on the circuit relationship.

Therefore, in the constant voltage stage, the voltage is constant and the current decays exponentially.

3.2 Consequences and risks of not following the CC-CV

If only constant current charging is used in the whole process, the voltage will continue to rise uncontrollably, which will inevitably exceed the maximum voltage, resulting in:

- Cathode lithium evolution:metallic lithium dendrite grows, piercing the diaphragm and causing internal short circuit.

- Electrolyte oxidation and decomposition:the positive potential is too high, and the electrolyte is unstable at high potential.

- Gas production, bulging and thermal runaway directly threaten safety.

If only constant voltage charging is used in the whole process: at the beginning, the battery voltage is very low, if the maximum voltage is directly applied, according to Ohm’s law, a very large transient impulse current will be generated. This current may far exceed the capacity of the battery core and connector, resulting in local overheating, melting of the connection point, and damage to the internal structure of the battery.

4 Technical necessity

Constant current (CC) and constant voltage (CV) two-stage charging is an engineering compromise and control art between “nonlinear electrochemical characteristics of batteries” and “linear controllable power supply” to achieve optimal, safe and efficient energy transfer. The constant current (CC) stage takes advantage of the small polarization of the battery in the low/medium SOC range to maximize the power and solve the pain point of “slow charging”; the constant voltage (CV) stage respects the physical reality that the polarization of the battery increases sharply in the high SOC range, strictly controls the voltage boundary, and solves the core problems of “unsafe overcharge” and “overcharge life”.

In the future, with the evolution of battery materials and charging technology, there may be more complex multi-stage curves or faster energy replenishment schemes, but the core concept of “first full sprint, then steady arrival” will still be the cornerstone of protecting the long-term and safe service of each battery. If we understand it, we can better understand the electric era in which we are living.