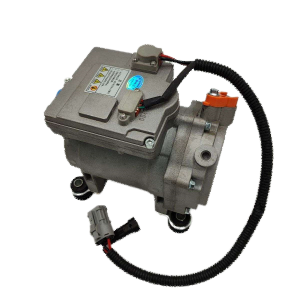

| MODEL NO. | SY —025CC | ||

| COMPRESS METHOD | Fully enclosed horizontal vortex compressor | ||

| COOLING LIQUD | R134a | ||

| SUGGETED VOLUME | 450~500g | ||

| Displacement | 25c c | ||

| Speed range | 1500~3500rpm | ||

| working pressure | Inhale pressure | 0.2~0.45Mpa | |

| Normal exhaust pressure | 1.2~1.8Mpa | ||

| Extreme exhaust pressure | 1.8~2.0M pa | ||

| Abnormal exhaust pressure | ≥2.0M pa | ||

| Pressure resistance test | high-pressure side | 10 Mpa |

| low-pressure side | 6 Mpa | |

| temperature | ambient temperature | ≤85℃ |

| delivery temperature | ≤110℃ | |

| Oil retention | 8% -10% of the system refrigerant capacity | |

| Evaporation temperature range | -10~12.5℃ | |

| Condensation temperature range | 26.7~68℃ | |

| Refrigerant leakage | <14g / year | |

| Frozen oil / oil amount | POE lubricating oil RL 68 H / 115 ± 5ml (factory oil injection volume) |

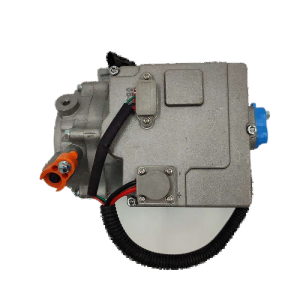

| surface | Cast aluminum surface sandblasting, corrosion prevention | |

| gross mass | 5.8kg | |

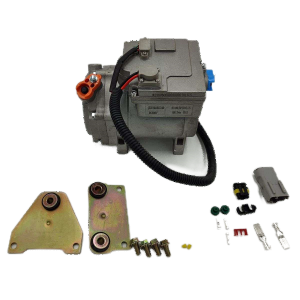

| way to install | Fit on the air conditioning shock base plate through the elastic damping element | |

| installation size | 161.5(L)X98(W)X155mm (H) | |

| Inner diameter of the suction pipe interface | Ф18.3mm | |

| Inner diameter of the exhaust pipe interface | Ф15.5mm |

Note: Under the extreme working pressure and abnormal working pressure, it will increase the failure rate of the compressor and shorten the service life of the compressor.

| Motor type | Permanent magnet brushless DC motor (BLDC) | |

| number of pole-pairs | 4 |

| The stator winding method | Three-phase Y-shaped | ||

| essential parameter | rated voltage | 320VDC | |

| Operating voltage range | 265V~450V | ||

| Rated input power | 900W | ||

| rated speed | 3000rpm | ||

| performance parameter | withstand voltage | <10mA @ AC1800V,1S | |

| Insulation characteristics | Pass 500VAC, insulation resistance> 50 MΩ (at 25℃) | ||

| Motor control mode | Square wave control | |

| Pole position detection method | No position sensor |

| Bus capacitor | 20uF | |

| Pre-charging road | not have | |

| Wave surge circuit | Yes (in the case of no precharging road, the starting capacitor charging current of the cooler can be limited to within 500A) | |

| Bus discharge resistance | 300K | |

| Auxiliary power supply mode | Low voltage power | |

| Low power use power range | 10.5V-27V | |

| Low-voltage rated voltage | 12V/24V | |

| Compressor high and low voltage power power sequence | First low voltage, then high voltage; high voltage first, then low voltage. | |

| communicating protocol | CAN |

| traffic rate | 250Kbps | |

| input characteristics | Rated input voltage | 320VDC |

| input voltage range | 265V~450V | |

| Rated input current | [email protected] | |

| Maximum input current | 6A | |

| Maximum input power | 2000W | |

| protection feature | overvoltage crowbar | 450V |

| undervoltage protection | 265V | |

| overcurrent protection | The equal power linear protection (2KW) within the operating voltage range is equivalent to the exhaust pressure of 2.5MPa |

| Overtemperature protection | 85℃ | |

| cooling-down method | Inhaled refrigerant for cooling | |

| levels of protection | IP67 |

Note: 1. The compressor controller is equipped with fault protection, and restart after 10 seconds.

- After five consecutive failures, the driver believes that the air conditioning system is abnormal and needs to be powered on and down again.

- Fault includes overvoltage, undervoltage, overtemperature and overcurrent (overcurrent fault is not included in the five faults).

- refrigeration performance

| speed | 2200 | 2600 | 2800 | 3200 |

| refrigerating capacity | 1800 | 2400 | 2800 | 3200 |

| interiorinput power | 700 | 830 | 960 | 1240 |

| EER | 2.5 | 2.8 | 2.8 | 2.6 |

Note: The speed error is ± 5%, the measured cooling capacity is not less than 93% of the value in the table, and the measured power should not be more than 110% of the value in the table.

- noise

| Speed Speed (rpm) | 2000 | 3000 | 3500 |

| noise (dB) | ≤62 | ≤65 | ≤70 |

Note: The noise sensor is installed at 15 cm directly above the compressor.

test condition:

| operating mode | evaporating temperature | condensing temperature | suction temperature | ambient temperature |

| 0.67℃ | 55.24℃ | 10.67℃ | 35℃ |

| System pressure protection switch | 2.5MPa closed, 2.45MPa recovery (for reference) |

| 0.18MPa closed, 0.23MPa recovery (for reference) | |

| Water component of the system refrigerant | 75 PPM (max.) |

| dustiness | 30mg (max.) |

| Maximum drive voltage | The main power supply voltage shall not be higher than 450VDC, otherwise the controller internal components. |

| Suction and exhaust pressure connection | The torque of the compressor suction and exhaust port of pressure bolt is 11 ± 1 N.M。 |

| Compressor installation Angle | The compressor body should not be tilted (the angle between the compressor main axis and the horizon should not be greater than 5°). |

| else | The electric compressor shall be avoided in the air outlet of the condenser to ensure adequate cooling of the controller. |

| The compressor needs the refrigerant cooling motor and the controller, the suction pipe should be added insulation pipe. | |

| In order to avoid the insulation drop caused by excessive moisture in the system, the compressor suction and vent should be installed into the closed system immediately (within 5 minutes) after opening. | |

| The compressor shall be installed with vibration reduction footpad to achieve vibration reduction and noise reduction purposes. | |

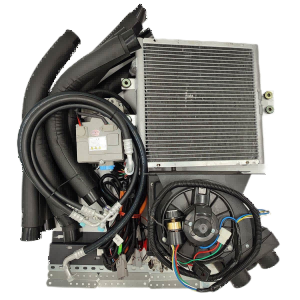

| · The heat dissipation capacity of the condenser should meet the system requirements, and the installation position should have enough heat dissipation space.

· There is energy storage filter capacitor inside the compressor controller. When high voltage is charged, precharging shall be adopted; otherwise, charged pulse current will cause impact damage to the relay and insurance. · Compressor branches recommend separate fuses and are not suitable for combination and use with parts related to vehicle safety (e. g., the same set of relays and insurance). · It is recommended to start the condenser fan 6 seconds before the compressor starts to reduce the pipe pressure; After the compressor stops, the condenser fan delays off for 6-10 seconds. · Under the extreme working pressure and abnormal working pressure, it will increase the failure rate of the compressor and shorten the service life of the compressor.

|

Reviews

There are no reviews yet.